Choosing the right HVAC system for industry and factory facilities is critical for process stability, worker safety and controlling heat, dust and air quality.

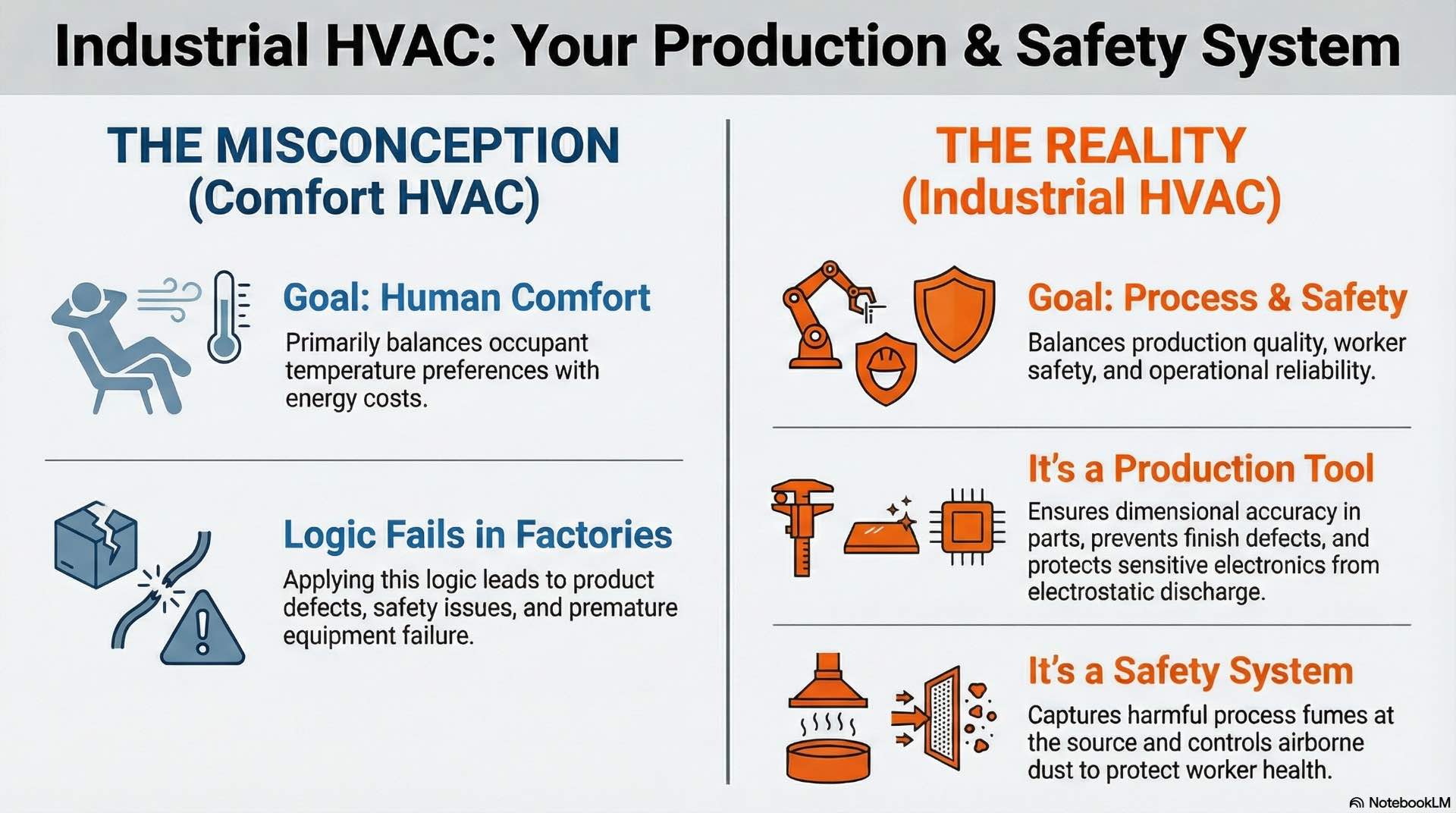

HVAC in industrial facilities operates as a production system rather than a comfort feature. Heat from machinery, airborne dust, process fumes, and variable shift schedules place demands on ventilation that differ fundamentally from office buildings. Getting this wrong affects product quality, worker health, and energy costs. Proper design treats industry environments as engineering problems requiring specific solutions for temperature stability, contaminant capture, and reliable operation. Understanding these differences shapes every decision in a factory HVAC installation from system selection to control strategy.

Most commercial approaches fail in manufacturing environments. Process loads change throughout the day. Dust clogs filters faster than maintenance schedules anticipate. Equipment generates heat in concentrated areas rather than distributed patterns. These realities define what works and what doesn’t.

The practices that follow address real manufacturing conditions. They cover ventilation design, temperature control for processes rather than people, filtration matched to actual particulate loads, zoning strategies, system selection, proper sizing, controls that respond to variable loads, energy efficiency that doesn’t compromise reliability, and verification methods that prove performance.

Treat HVAC as a production and safety system, not comfort equipment

Why industrial processes drive HVAC decisions

Manufacturing operations generate thermal and air quality challenges that define HVAC requirements. A stamping press producing 200°F surface temperatures creates a different load than office workers at computers. Welding operations release metal fumes that must be captured before reaching the breathing zone effectively. Painting lines require controlled humidity to prevent finish defects in factory production areas.

Process requirements determine setpoints and tolerances far more than human comfort preferences. A pharmaceutical facility may need ±1°F temperature control for product stability. A plastics molding operation needs consistent conditions for dimensional accuracy in finished parts. An electronics assembly area requires low humidity to prevent electrostatic discharge damage in sensitive components. These aren’t comfort preferences—they’re production requirements with measurable quality impacts.

Risks of applying commercial HVAC logic to factories

Commercial buildings balance comfort and energy cost. Industry facilities balance production quality, safety, and operational reliability. Applying office building logic causes predictable failures.

Oversized commercial equipment short-cycles in factory applications, providing poor humidity control and unstable temperatures throughout the space. Standard filtration schedules allow filter loading to degrade performance before replacement occurs. Comfort-based setpoints ignore process requirements. Zone definitions based on floor area rather than process locations create hot spots and contamination pathways that affect product quality.

Field experience shows these misapplications cost more than proper industrial design. Rework from temperature-related quality defects, worker compensation claims from heat stress, and premature equipment failures from contaminated air all exceed the savings from using cheaper commercial approaches.

Design HVAC ventilation around heat, dust, and process emissions

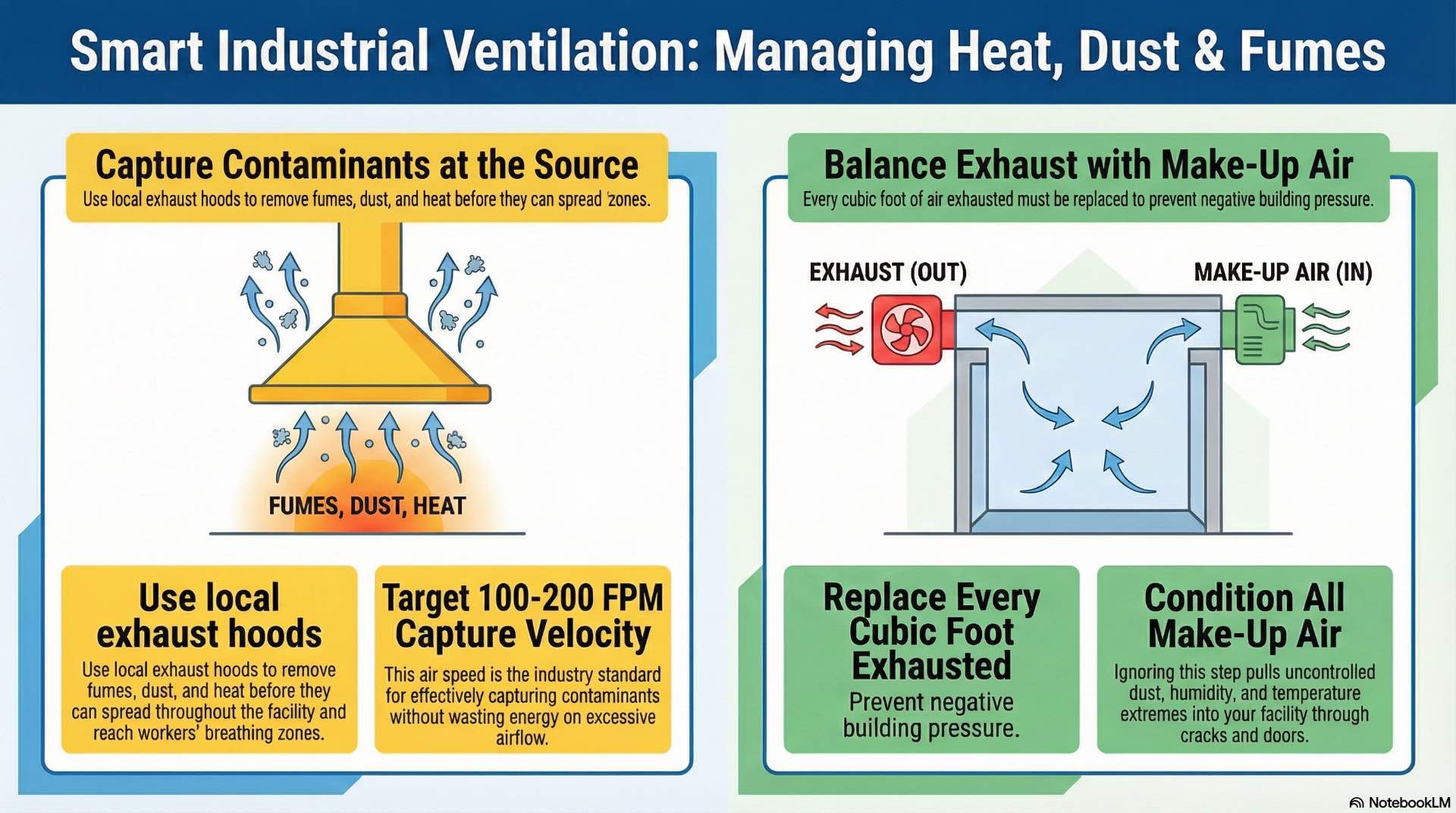

Source capture exhaust as a primary best practice

Capturing contaminants at their source prevents them from spreading through the facility. A weld hood positioned six inches from the arc captures fumes before they spread to other workers. A grinding station exhaust removes metal particles before they settle on adjacent equipment in the factory.

Source capture requires calculating capture velocity—the air speed needed to overcome thermal plumes, cross-drafts, and contaminant momentum. Most industry applications need 100-200 feet per minute capture velocity for effective collection. Higher velocities waste energy; lower velocities allow contaminant escape. Hood design and duct sizing follow from proper capture velocity calculations.

Balancing exhaust and make-up air correctly

Every cubic foot of air exhausted must be replaced. Ignoring make-up air creates negative pressure that pulls unconditioned air through doors, cracks, and openings. This infiltration brings in dust, humidity, and temperature extremes that the HVAC system then struggles to manage.

Proper make-up air systems condition replacement air before delivery to factory spaces. In winter, this means heating incoming air to avoid cold drafts on workers near entry points. In summer, it may mean cooling and dehumidification. The make-up air volume should match or slightly exceed exhaust volume to maintain neutral or slightly positive building pressure.

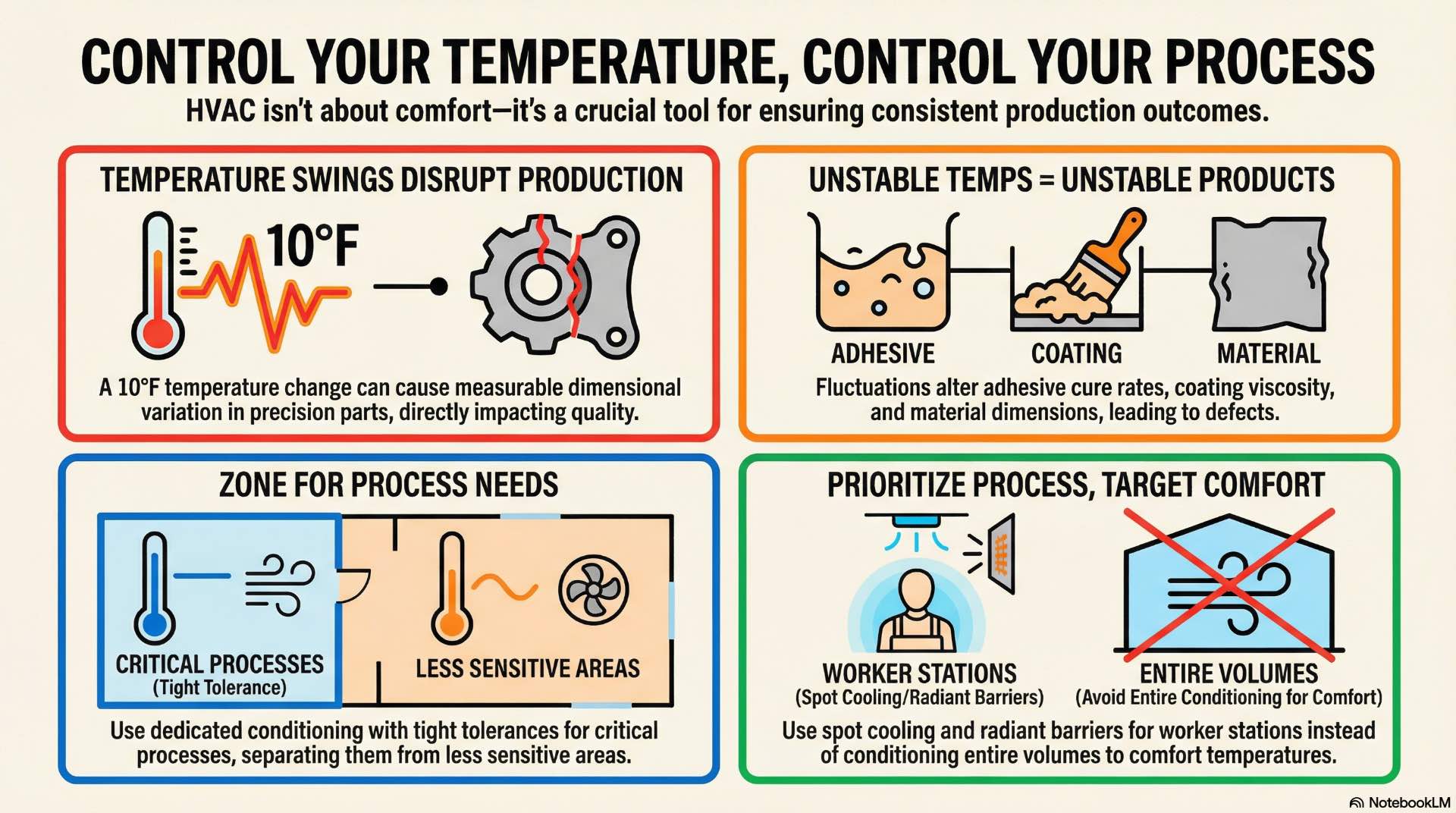

Apply HVAC temperature control for process stability

Maintaining stable conditions for equipment and materials

Temperature swings affect dimensional stability, cure times, viscosity, and dozens of other process parameters in industry operations. A 10°F temperature change in a machining area can cause measurable dimensional variation in precision parts during production. Adhesive cure rates double or halve with 15°F changes. Coating viscosity shifts affect spray patterns and film thickness on finished products.

Control strategies must match process requirements. Critical processes need dedicated conditioning with tight setpoint tolerance and fast response. Less sensitive areas can use wider deadbands and slower response to reduce energy consumption. Zoning these different requirements into separate control loops prevents interference between areas with different needs.

When comfort cooling should be secondary

Worker comfort matters for productivity and safety in any factory environment. Heat stress causes errors, injuries, and illness. However, process requirements often conflict with comfort preferences.

Practical approaches address both needs separately. Spot cooling delivers conditioned air directly to worker stations while allowing surrounding areas to run warmer. Radiant barriers block heat transfer from hot equipment to workers nearby. Personal cooling equipment helps workers in areas where ambient temperature control isn’t feasible for industry processes. These targeted solutions cost less than conditioning entire volumes to comfort temperatures.

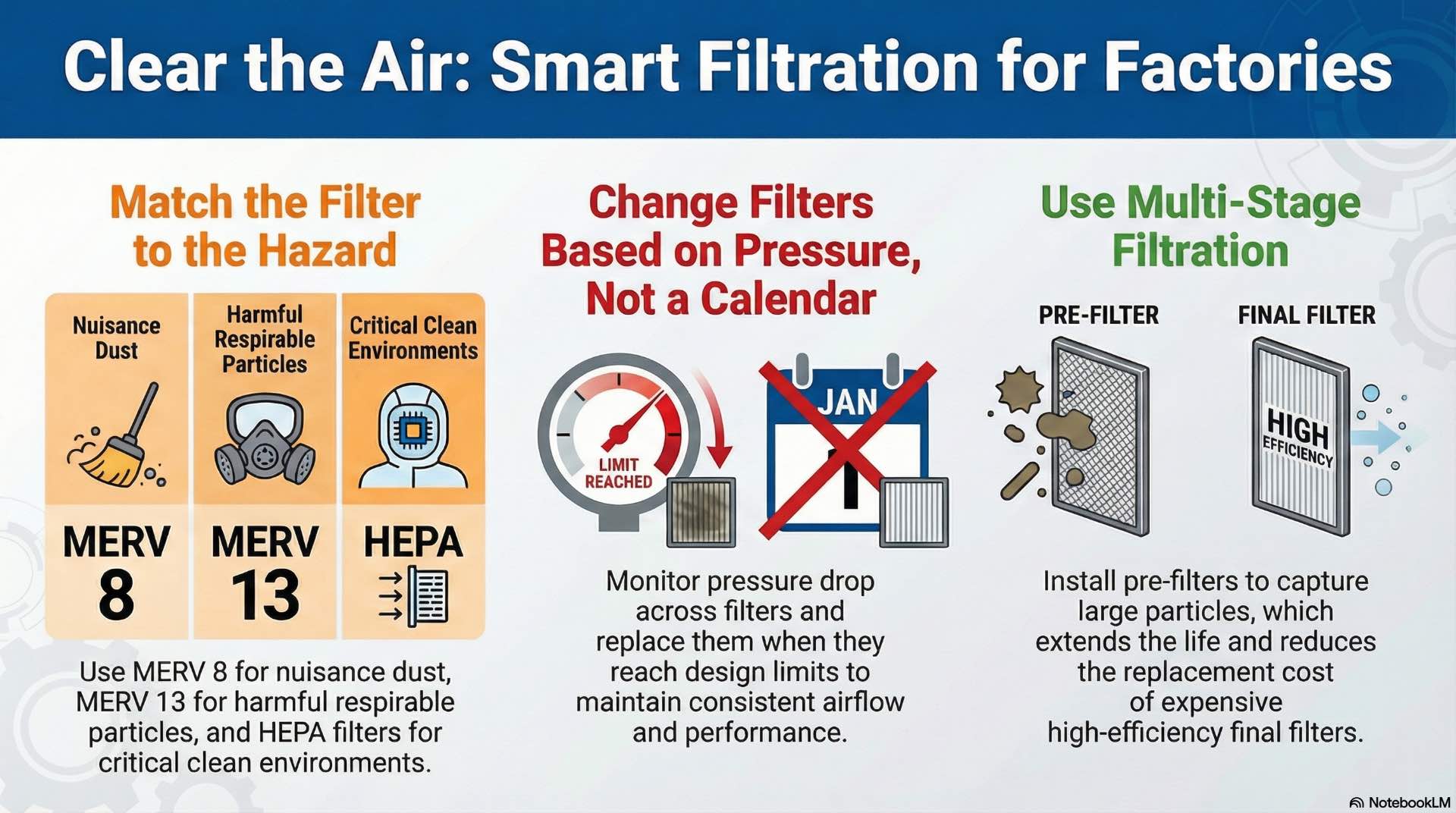

Use filtration and air quality control suited to factory conditions

Matching filter efficiency to dust and particulate loads

Filter selection depends on what you’re removing and why. MERV 8 filters capture large particles but pass respirable dust. MERV 13 filters catch most industrial particulates but load faster in dirty environments than standard schedules anticipate. HEPA filtration removes 99.97% of 0.3-micron particles but requires significant fan power and frequent replacement.

Match filter efficiency to actual hazards in your factory. Nuisance dust may only need MERV 8. Respirable silica requires MERV 13 minimum. Pharmaceutical applications may need HEPA. Pre-filters extend the life of high-efficiency final filters by capturing large particles first. Multi-stage filtration systems balance protection with operating cost in industry applications.

Planning maintenance to prevent performance loss

Filter pressure drop increases as filters load. This reduces airflow unless fan speed increases to compensate. Most facilities wait too long to change filters, accepting degraded HVAC performance until pressure drop becomes obvious.

Establish pressure drop limits from system design, not arbitrary schedules. Monitor differential pressure across filter banks continuously. Replace filters when pressure drop reaches design limits, not when calendar intervals arrive. In high-dust factory environments this may mean weekly filter changes for heavy loads depending on process conditions. In cleaner areas, quarterly changes may suffice.

Separate clean and dirty areas using zoning and pressure control

Using pressure relationships to control airflow

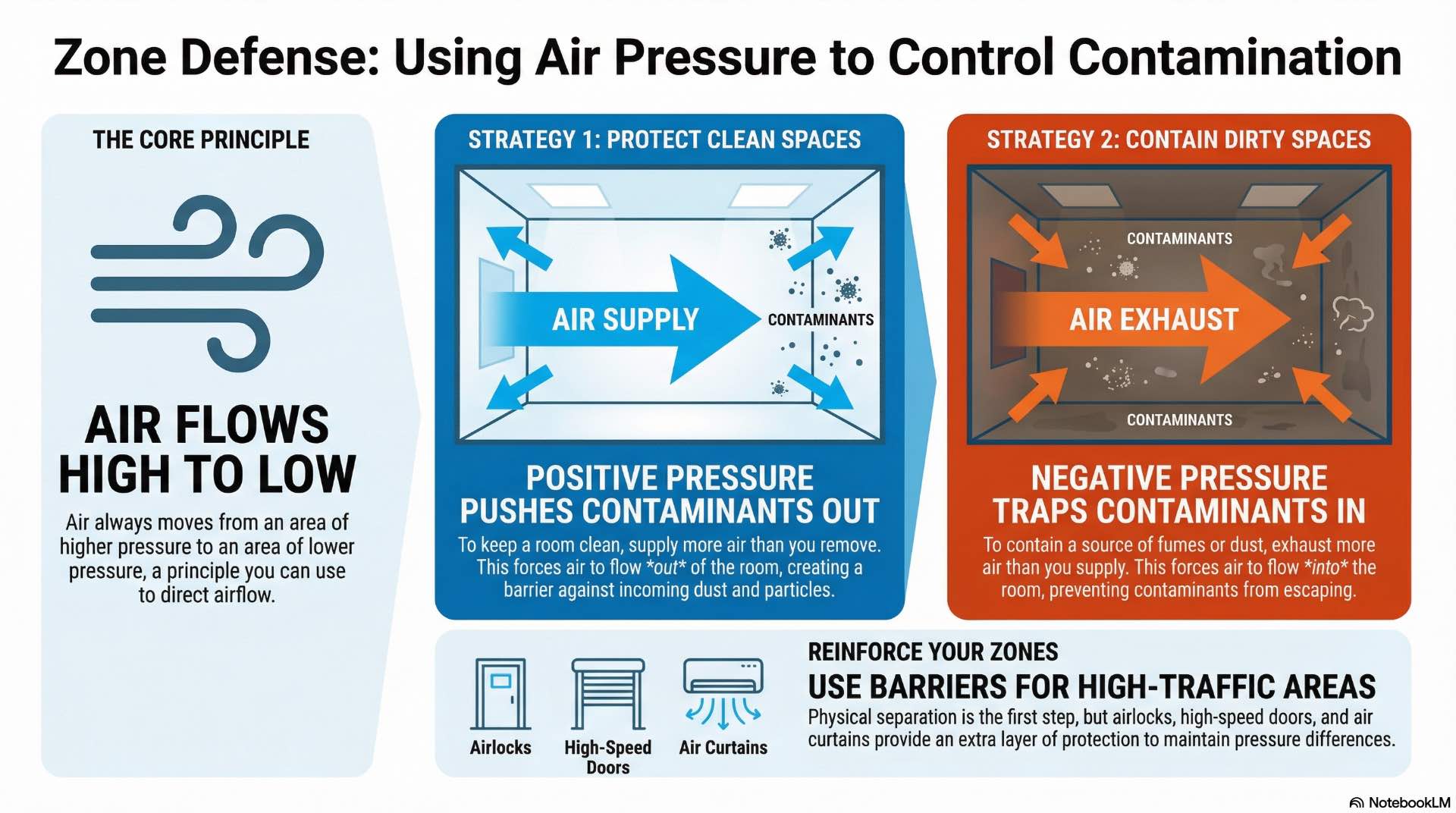

Air flows from high pressure to low pressure. This principle controls contamination transfer between spaces in any industry facility. A cleanroom maintained at positive pressure relative to surrounding areas prevents outside contamination from entering the controlled space. A paint booth at negative pressure contains fumes within the booth effectively.

Pressure differentials of 0.02-0.05 inches water column typically suffice for industrial applications. Higher differentials waste energy and stress doors and penetrations. Maintaining these differentials requires controlling supply and exhaust volumes precisely, with makeup air balancing the system.

Preventing cross-contamination between spaces

Physical separation through walls and doors provides the first barrier in factory layouts. Pressure relationships provide the second. Airlocks between clean and dirty areas provide a third layer of contamination protection for critical processes.

Door traffic disrupts pressure relationships temporarily. High-speed roll-up doors minimize opening time in busy industry facilities. Air curtains at frequently used openings maintain separation without physical barriers. Vestibules with sequential doors prevent simultaneous opening to both zones and maintain HVAC system effectivenessthroughout operations.

Select HVAC system types that fit industrial operation

Rooftop units, AHUs, and make-up air systems in factories

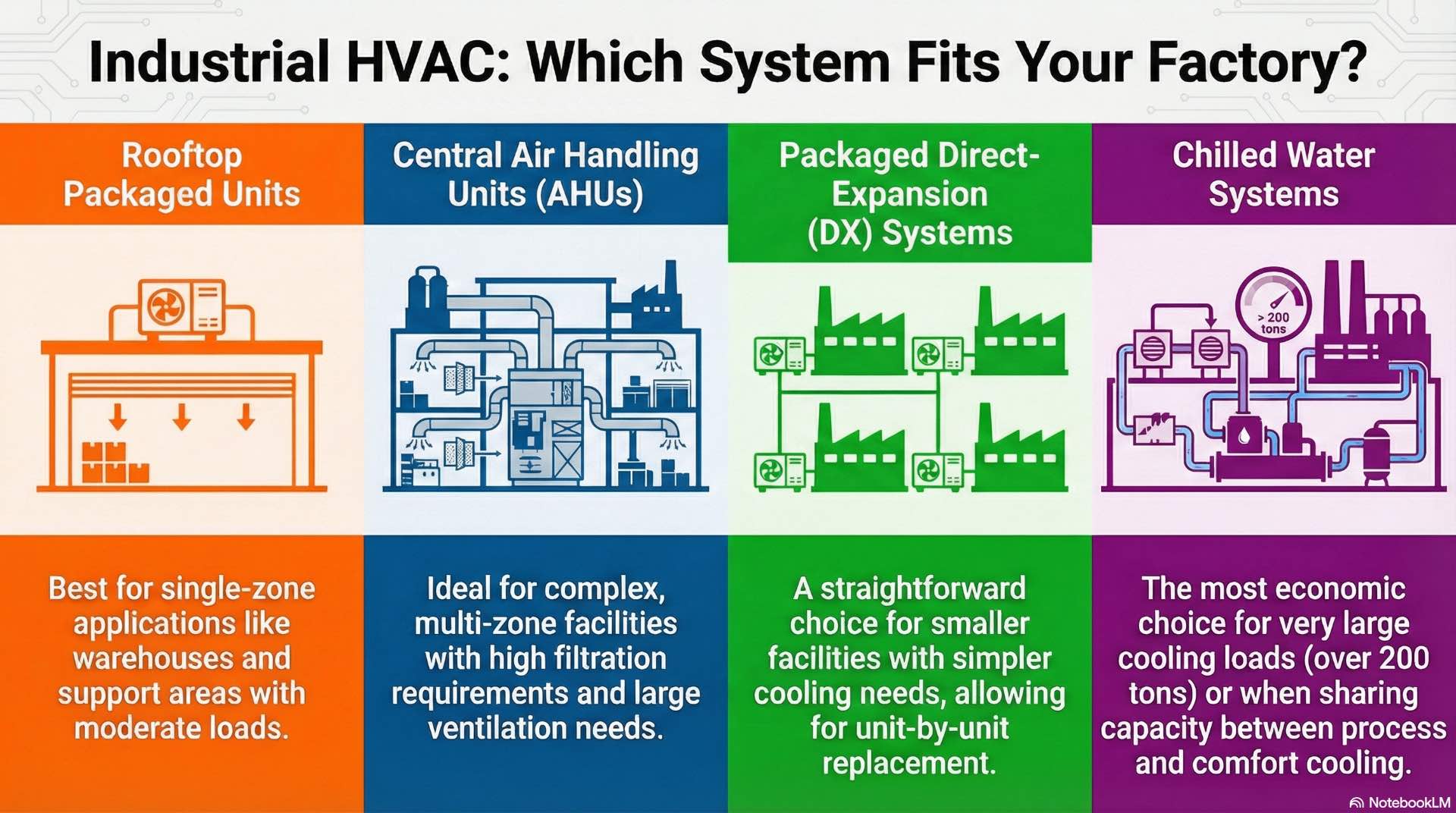

Rooftop packaged units suit single-zone applications with moderate loads. They’re cost-effective for warehouses, simple manufacturing spaces, and support areas. Limitations appear when multiple zones need independent control or when loads vary significantly across the factory floor.

Central air handling units serve complex facilities with multiple zones, high filtration requirements, or large ventilation needs. They cost more initially but provide better control and easier maintenance access plus longer service life. Industrial AHUs use heavier construction and corrosion-resistant materials compared to commercial units. Make-up air units condition replacement air for spaces with high exhaust volumes.

When packaged or chilled water systems work better

Packaged direct-expansion systems suit smaller industry facilities with straightforward cooling needs. They’re simpler to install, require less infrastructure, and can be replaced unit-by-unit as equipment ages over time.

Chilled water systems make economic sense when cooling loads exceed roughly 200 tons or when process cooling shares capacity with comfort cooling in large factory operations. Central chillers achieve higher efficiency at large scale. The piping infrastructure costs more initially but allows flexible expansion through multiple chillers in various configurations.

Size HVAC systems for real operating conditions

Avoiding oversizing and unstable operation

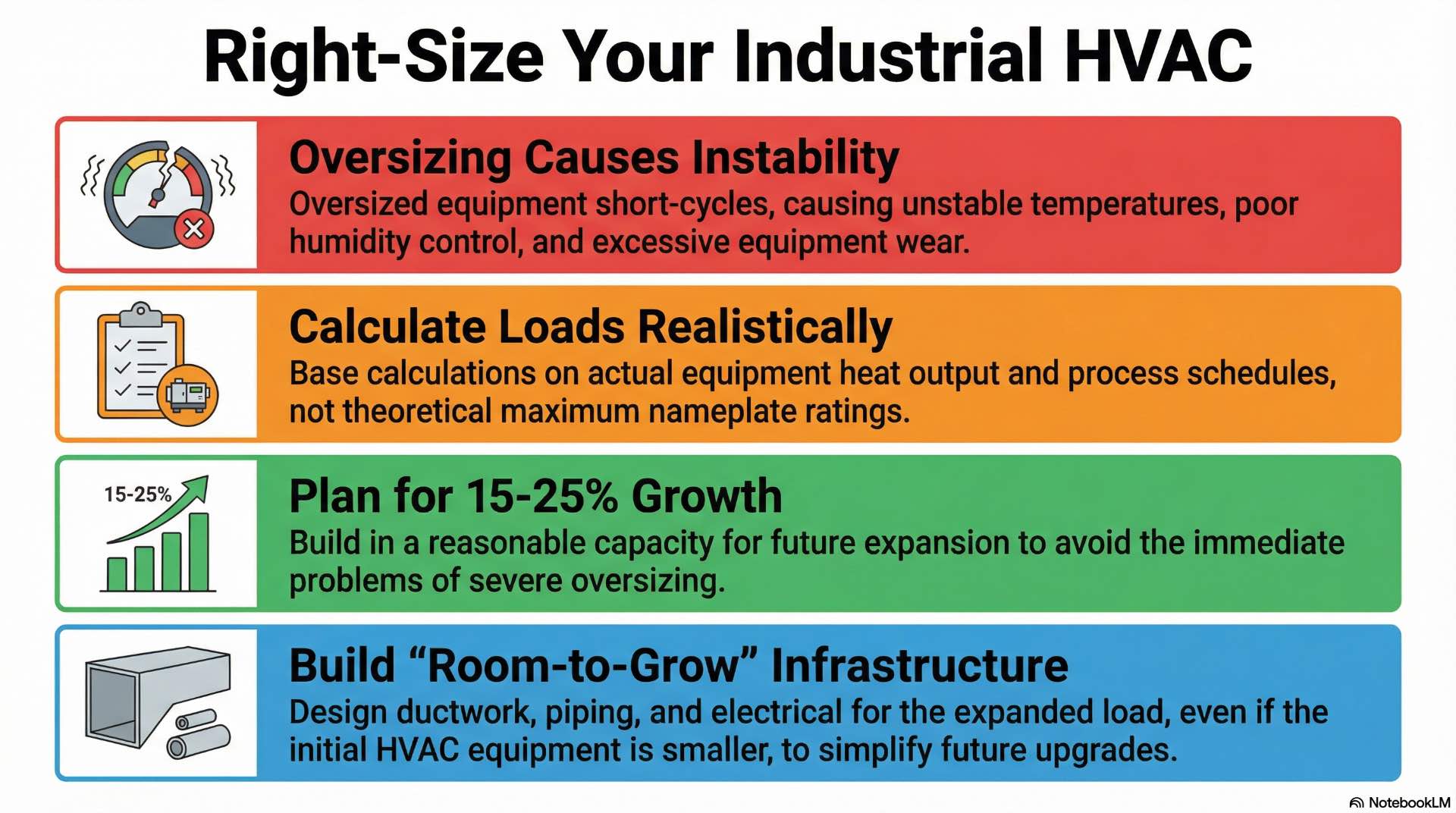

Oversized equipment short-cycles—starting, reaching setpoint quickly, stopping, then restarting when temperature drifts. This causes temperature instability and poor humidity control in factory spaces, plus excessive wear and wasted energy. Size systems to match actual peak loads, not worst-case assumptions stacked on safety factors.

Accurate load calculations require realistic inputs for industry applications. Use actual equipment heat output, not nameplate ratings that assume maximum continuous operation. Account for process schedules that reduce peak loads across the facility simultaneously. Consider building envelope improvements that reduce solar and conduction loads over time.

Allowing capacity for future process changes

Future expansion needs reasonable allowance, not excessive overcapacity. Plan for 15-25% growth capacity depending on business projections. This allows moderate expansion without major system replacement while avoiding the problems of severe oversizing.

Design infrastructure—ductwork, piping, electrical capacity—for the expanded load even if initial HVAC equipment is sized smaller. Adding a second chiller or additional AHU is straightforward if the supporting infrastructure exists for expansion needs. Retrofitting undersized ductwork or electrical service in a factory costs far more than initial oversizing.

Implement controls that keep HVAC performance stable

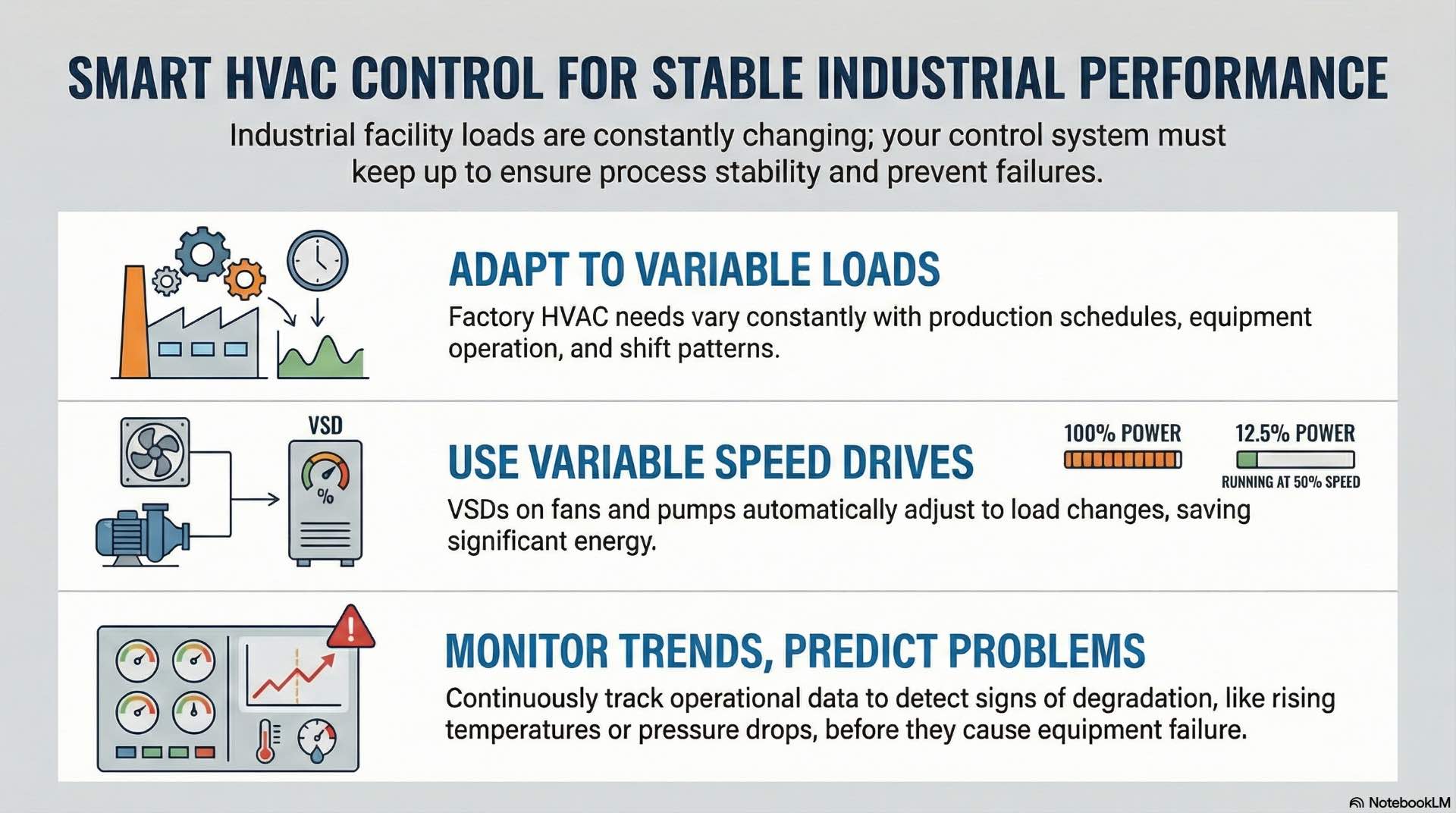

Control strategies for variable loads and shifts

Industrial loads vary with production schedules, equipment operation, and shift patterns in factory environments. A facility running one shift needs different control strategies than three-shift continuous operation. Batch processes create periodic load spikes while continuous processes create steady loads.

Variable speed drives on fans and pumps allow HVAC equipment to follow load changes efficiently. Running a fan at 50% speed uses only 12.5% of full-speed power. This efficiency gain requires controls that sense load changes and respond appropriately. CO₂-based demand-controlled ventilation adjusts outside air based on occupancy. Temperature reset strategies adjust supply air based on zone demands across the industry facility.

Monitoring trends to detect problems early

Control systems generate operational data continuously. Trending this data reveals degradation before failures occur in factory HVAC systems. Rising supply air temperature indicates dirty coils or low refrigerant charge. Increasing filter pressure drop shows filter loading. Growing deviation between setpoint and actual temperature suggests sensor drift or control valve problems requiring attention.

BMS integration provides centralized monitoring and historical data storage. Alarm thresholds catch acute problems as they occur. Trend analysis catches gradual degradation that threshold alarms miss over time.

Improve energy efficiency without compromising reliability

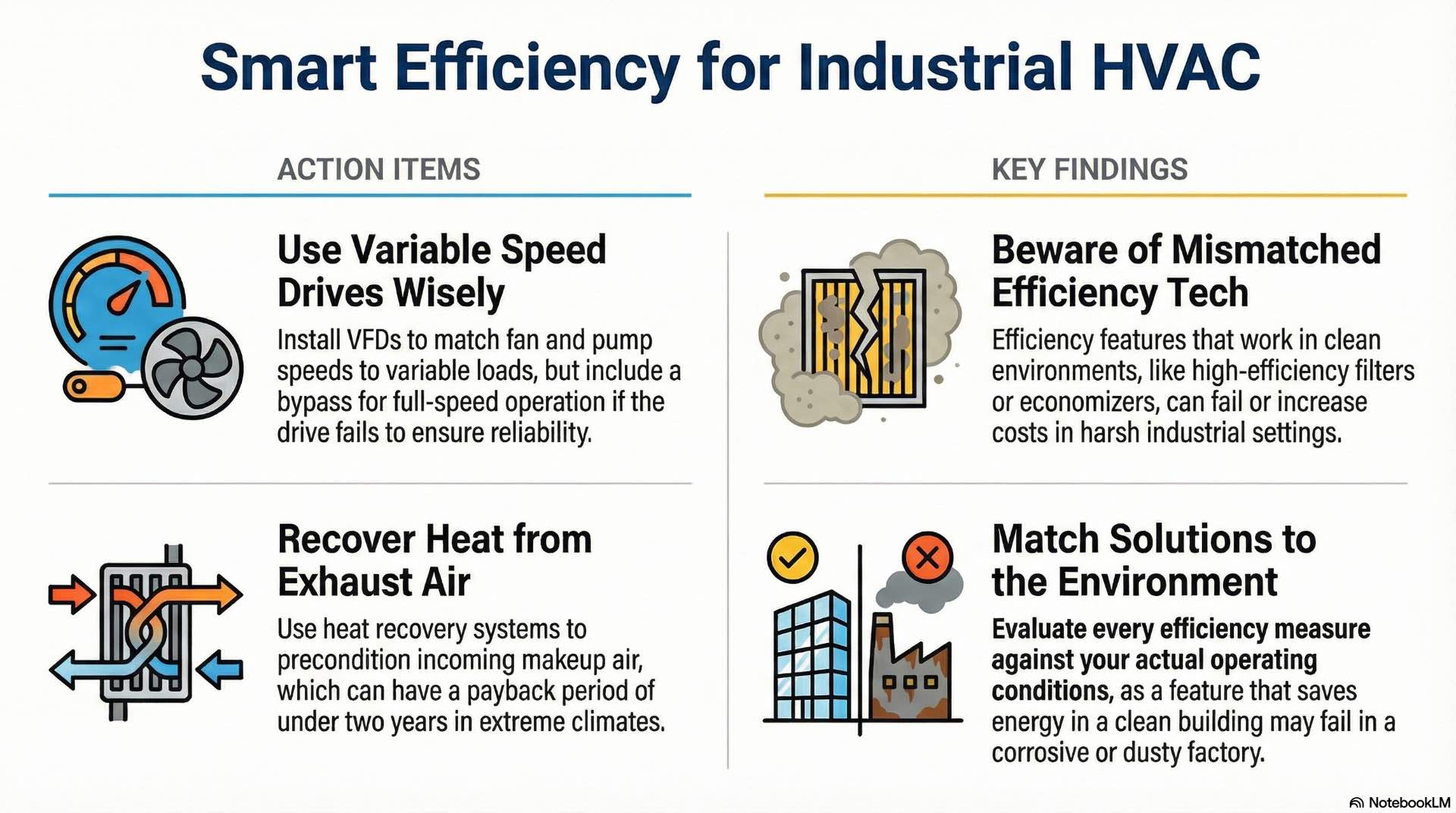

Applying variable speed and heat recovery carefully

Variable frequency drives reduce energy consumption dramatically when loads vary in industry operations. They also add complexity and potential failure modes. In critical applications, include bypass capability for full-speed operation if the drive fails.

Heat recovery systems capture exhaust energy to precondition makeup air entering the building. Effectiveness depends on temperature differential between exhaust and outdoor air. In mild climates, payback may be marginal. In extreme climates, payback can be under two years. Enthalpy wheels recover heat and moisture while plate exchangers recover sensible heat only for factory applications. Choose based on climate and humidity requirements.

Avoiding efficiency features that fail in harsh environments

Not every efficiency feature suits industrial applications. High-efficiency filters in dusty environments load quickly, increasing fan energy and requiring frequent replacement. Economizer dampers in areas with outdoor contamination bring in particles that the filtration system must handle in factory spaces.

Evaluate efficiency measures against the actual operating environment. Energy recovery in corrosive exhaust streams fails prematurely and costs more than projected savings. A feature that saves energy in clean commercial buildings may cost more than it saves in harsh industrial environments.

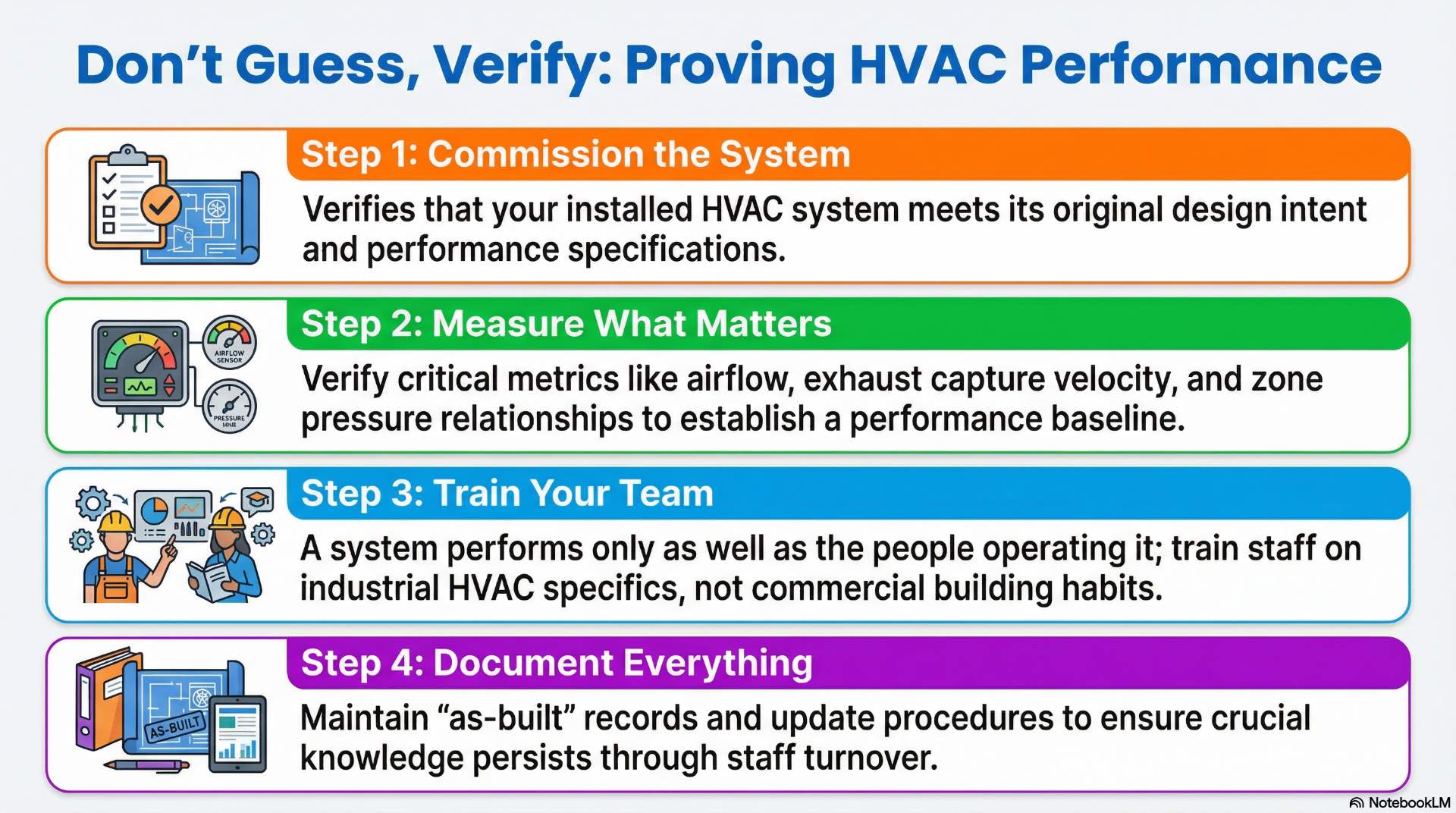

Verify HVAC performance through commissioning and operation

Airflow, exhaust capture, and pressure verification

Commissioning proves that installed systems meet design intent in factory HVAC installations. Measure airflow at every supply grille and return throughout the facility. Verify exhaust capture velocity at source capture hoods. Document pressure relationships between zones. Test control sequences through full range of operation under realistic loads.

These measurements establish baseline performance for any factory or industry facility. Repeating them annually detects degradation. Comparing actual performance to design identifies installation defects or equipment problems that need correction in industry facilities.

Training and documentation as a long-term best practice

Systems perform only as well as the people operating and maintaining them. Training maintenance staff on industrial HVAC specifics prevents commercial building habits from degrading system performance. Document setpoints, control sequences, and maintenance procedures so knowledge persists through staff turnover over time.

As-built documentation captures what was actually installed, not just what was designed for the factory. Update documentation when changes occur. Accurate records reduce troubleshooting time and prevent repeated mistakes.

Effective HVAC practices for industrial facilities start with understanding that these systems serve production and safety requirements, not just comfort. Matching system types, sizing, controls, and maintenance practices to actual operating conditions determines long-term success. Industry environments demand real-world designs that handle heat, dust, and variable loads rather than applying commercial building assumptions. The practices outlined here provide a framework for decisions that maintain process stability in factory operations, protect workers, control energy costs, and deliver reliable performance over the equipment lifecycle.