UPS system fundamentals, UPS topologies, battery technologies, power conditioning and UPS maintenance are explained to guide reliable critical power design.

Modern facilities need clean power without interruption. An UPS system protects equipment from outages by using different UPS topologies that convert and switch between sources. Advanced battery technologies store reserve energy, while integrated power conditioning removes noise and harmonics from incoming lines. Regular UPS maintenance confirms every component performs within specification so critical loads remain stable.

Power continuity isn’t optional anymore. Data centers lose revenue during every second of downtime, hospitals risk patient safety when monitors fail, and industrial controllers halt production if voltage sags. That’s why you need a robust UPS system architecture built from proven UPS topologies, reliable battery technologies, comprehensive power conditioning, and scheduled UPS maintenance protocols.

Understanding UPS System Fundamentals

Role of UPS System in Critical Power Protection

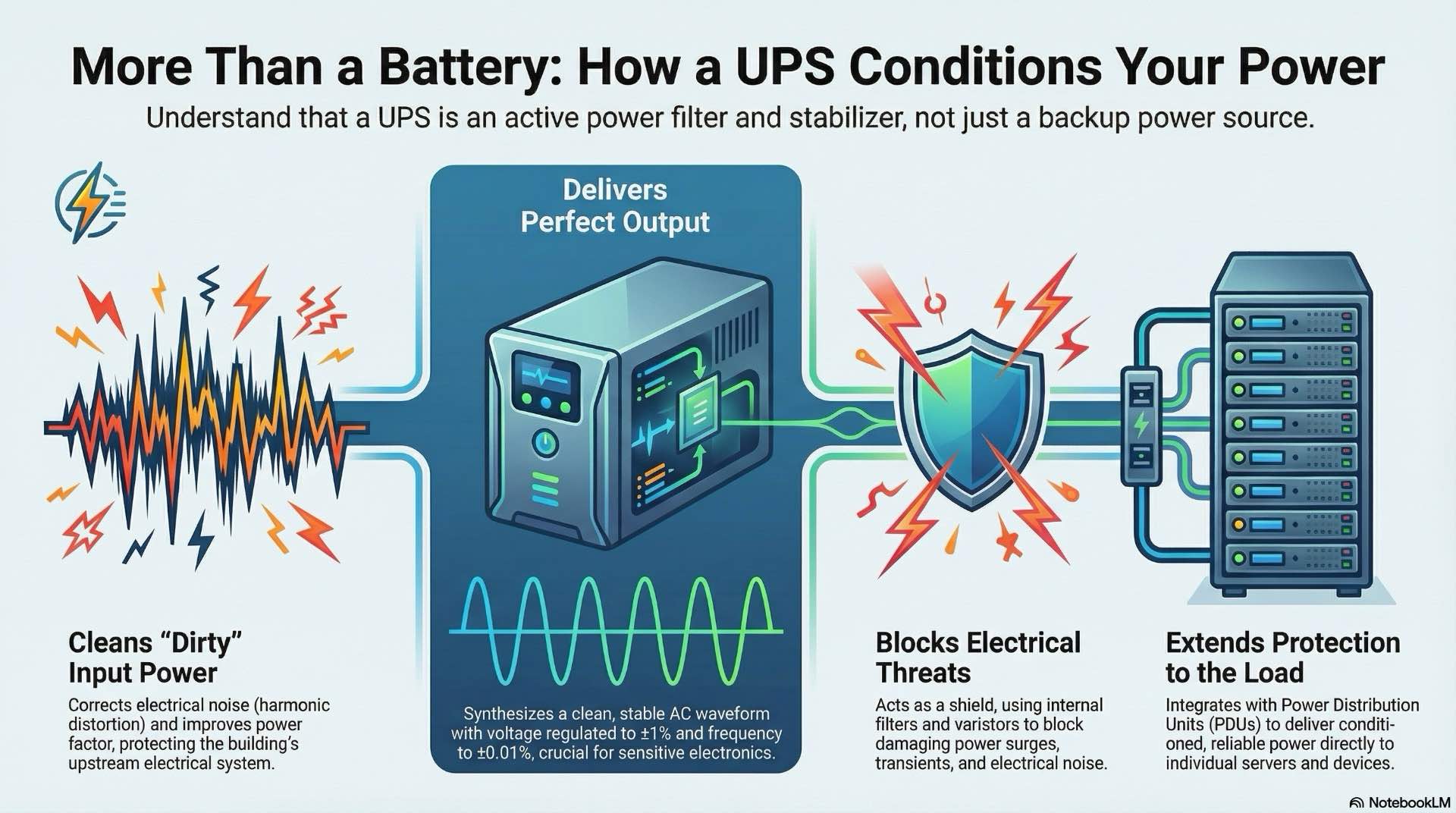

Uninterruptible power supplies bridge the gap between utility failure and backup generator startup. Every unit converts alternating current to direct current through power conditioning stages, then inverts that DC back to clean AC at the output. You’ll find rectifier sections that charge batteries while supplying the inverter, and static bypass paths in most UPS topologies that route input straight to the load when the inverter can’t handle surge currents.

Controllers inside the installation monitor voltage through advanced power conditioning circuits. When line power drops below threshold, the inverter draws from battery technologies instantly—no switching delay means your servers never see a glitch. Load equipment doesn’t care whether power comes from utility or battery; it sees constant voltage maintained by UPS topologies. Different UPS topologies handle this transition with varying speed and efficiency based on their power conditioning approach.

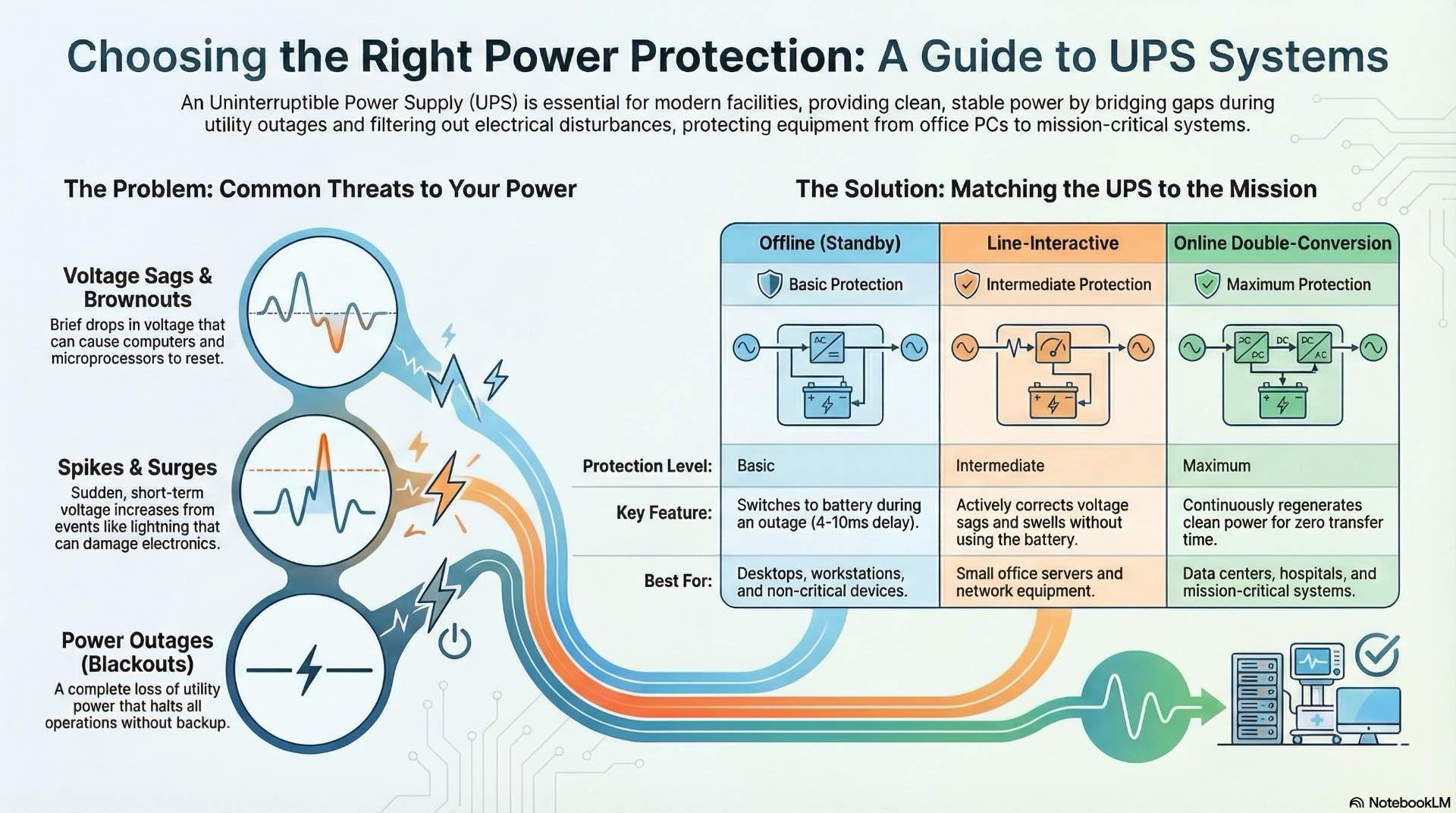

Common Power Problems UPS System Address

Voltage sags reduce input by 10 to 30 percent for milliseconds or minutes. Motors starting nearby cause brownouts that reset microprocessors. An uninterruptible power supply with proper power conditioning protects against spikes that jump hundreds of volts above nominal. Transients from lightning inject noise that scrambles circuits unless power conditioning filters intercept them.

Frequency drift happens when generators struggle to maintain 50 or 60Hz under varying load. Different UPS topologies address this through independent oscillators. Harmonic distortion from non-linear equipment adds third, fifth, and seventh harmonics. Total harmonic distortion above 5 percent shortens transformer life. Effective power conditioning and appropriate UPS topologies eliminate these issues while proper UPS maintenance ensures continued protection.

Where UPS Systems Are Used in Modern Facilities

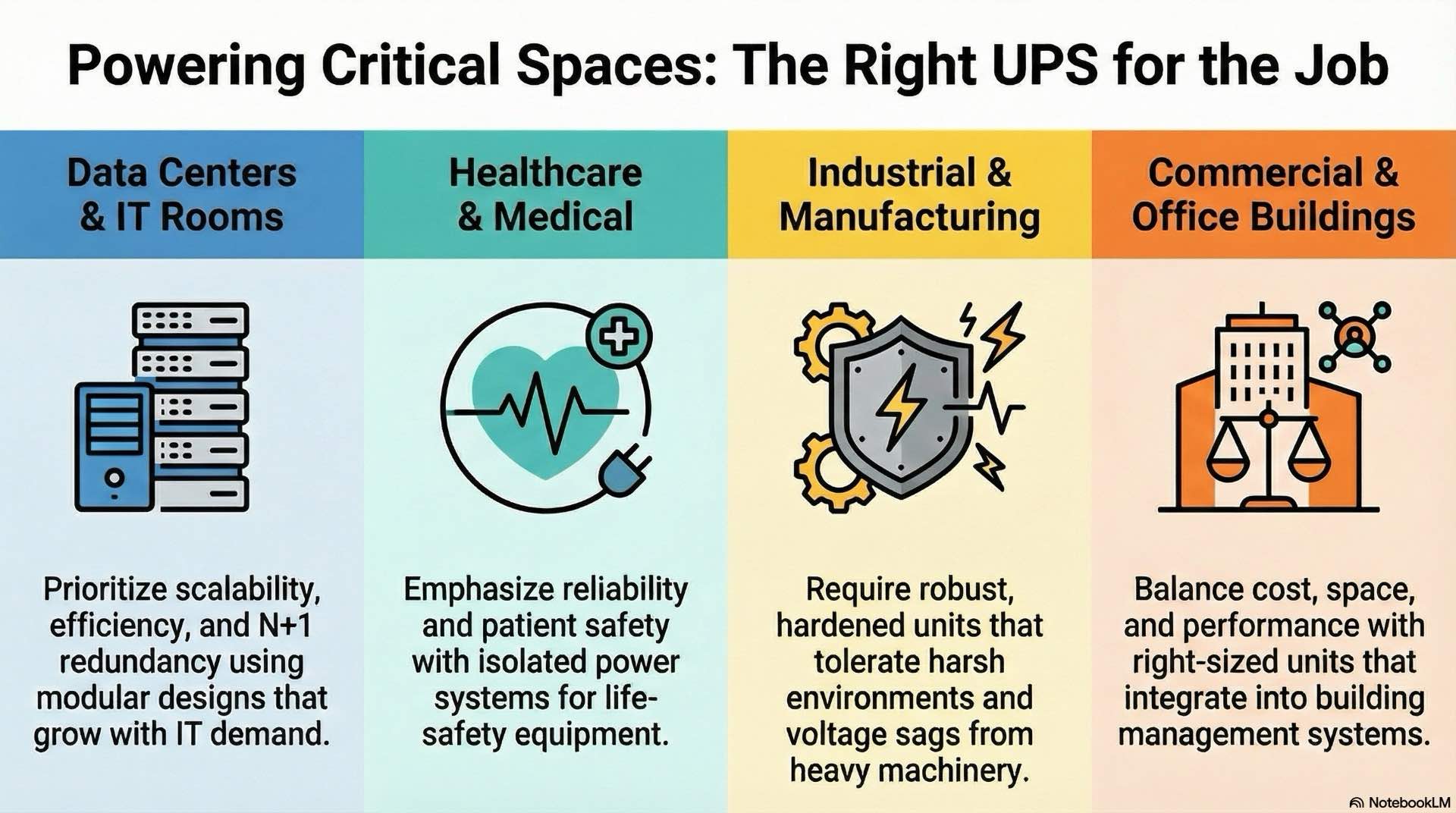

IT rooms rely on rack-mounted UPS system units to protect switches, routers, and storage arrays. Data center rows deploy modular UPS topologies that scale from 10kW to megawatts. Medical imaging labs use isolated UPS system designs with advanced power conditioning to prevent ground loops. Battery technologies in these installations determine runtime and footprint, with UPS maintenance schedules ensuring uninterrupted service.

Industrial sites protect programmable logic controllers with specific UPS topologies matched to harsh environments. Telecom central offices keep voice switches online through redundant UPS system designs. Building management platforms require constant operation, so HVAC, lighting, and security systems depend on reliable UPS topologies. Regular UPS maintenance and appropriate battery technologies keep these critical systems running.

UPS Topologies and Power Protection Levels

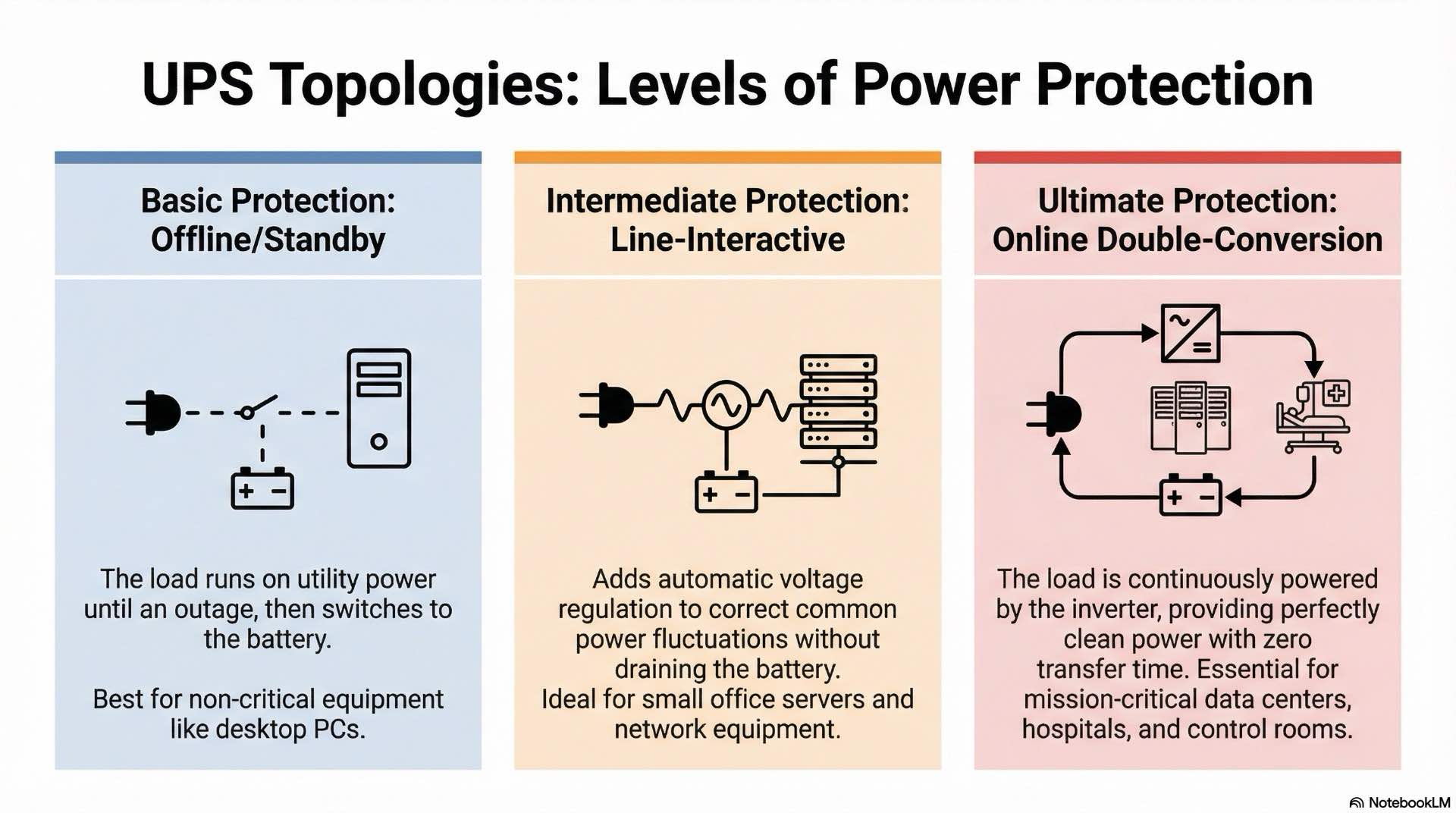

Offline or Standby UPS System

Offline designs represent basic UPS topologies where load stays connected to utility most of the time. An automatic transfer switch monitors input and swaps to battery inverter when voltage drops. Transfer time runs 4 to 10 milliseconds in these UPS topologies, fast enough for desktops but too slow for servers. Limited power conditioning occurs during normal operation compared to other UPS topologies.

These UPS topologies cost less because inverter and battery only activate during outages. Efficiency stays above 95 percent since you’re not running double conversion continuously in standby UPS topologies. UPS maintenance is simpler—fewer components mean fewer failure points. Power conditioning capability depends on whether you select line-interactive or basic offline UPS topologies. Battery technologies used in offline UPS topologies typically emphasize low cost over performance.

Line-Interactive UPS System

Line-interactive units add automatic voltage regulation to basic UPS topologies. A tapped transformer provides continuous power conditioning by correcting sags and swells without switching to battery. The inverter stays connected in parallel in line-interactive UPS topologies, ready to take over in 2 to 4 milliseconds. This approach to power conditioning balances cost and protection.

Small offices use these UPS topologies for cost-effective protection with adequate power conditioning. They handle minor grid fluctuations without draining batteries, maximizing runtime when real outages occur. Typical capacity in line-interactive UPS topologies ranges from 500VA to 3kVA per unit. Battery technologies in these UPS topologies typically use VRLA chemistry for simplicity, with UPS maintenance focused on battery replacement cycles.

Online Double-Conversion UPS System

Double-conversion designs represent premium UPS topologies where load feeds through inverter continuously. Rectifier converts AC to DC, battery floats on DC bus in all online UPS topologies. The inverter synthesizes clean AC from DC through constant power conditioning. Load never sees utility directly in double-conversion UPS topologies—input could vanish instantly and output wouldn’t change.

Zero transfer time makes these UPS topologies ideal for mission-critical gear requiring continuous power conditioning. You’ll find online double-conversion UPS topologies in data centers, hospitals, and control rooms. Efficiency dropped below 90 percent in older double-conversion UPS topologies, but modern units with eco-mode reach 96 percent. Power conditioning in online UPS topologies is continuous and comprehensive, protecting against all disturbances. Advanced battery technologies maximize runtime while minimizing footprint in these premium UPS topologies.

Choosing the Right UPS Topology for the Application

Match transfer time to equipment sensitivity when selecting among available UPS topologies. Desktop workstations tolerate 10 milliseconds found in standby UPS topologies; blade servers need zero-transfer online UPS topologies. Consider input power quality—if you see frequent sags, line-interactive UPS topologies make sense. Sites with dirty power demand double-conversion UPS topologies with continuous power conditioning.

Evaluate total cost of ownership over 10 years across different UPS topologies. Higher-efficiency UPS topologies save thousands in electricity and cooling. Factor in UPS maintenance labor: modular UPS topologies let you swap components without taking the whole UPS system offline. Battery technologies affect both initial cost and long-term replacement expenses across all UPS topologies. Select UPS topologies that match your power conditioning requirements and UPS maintenance capabilities.

Core UPS Components and Power Path

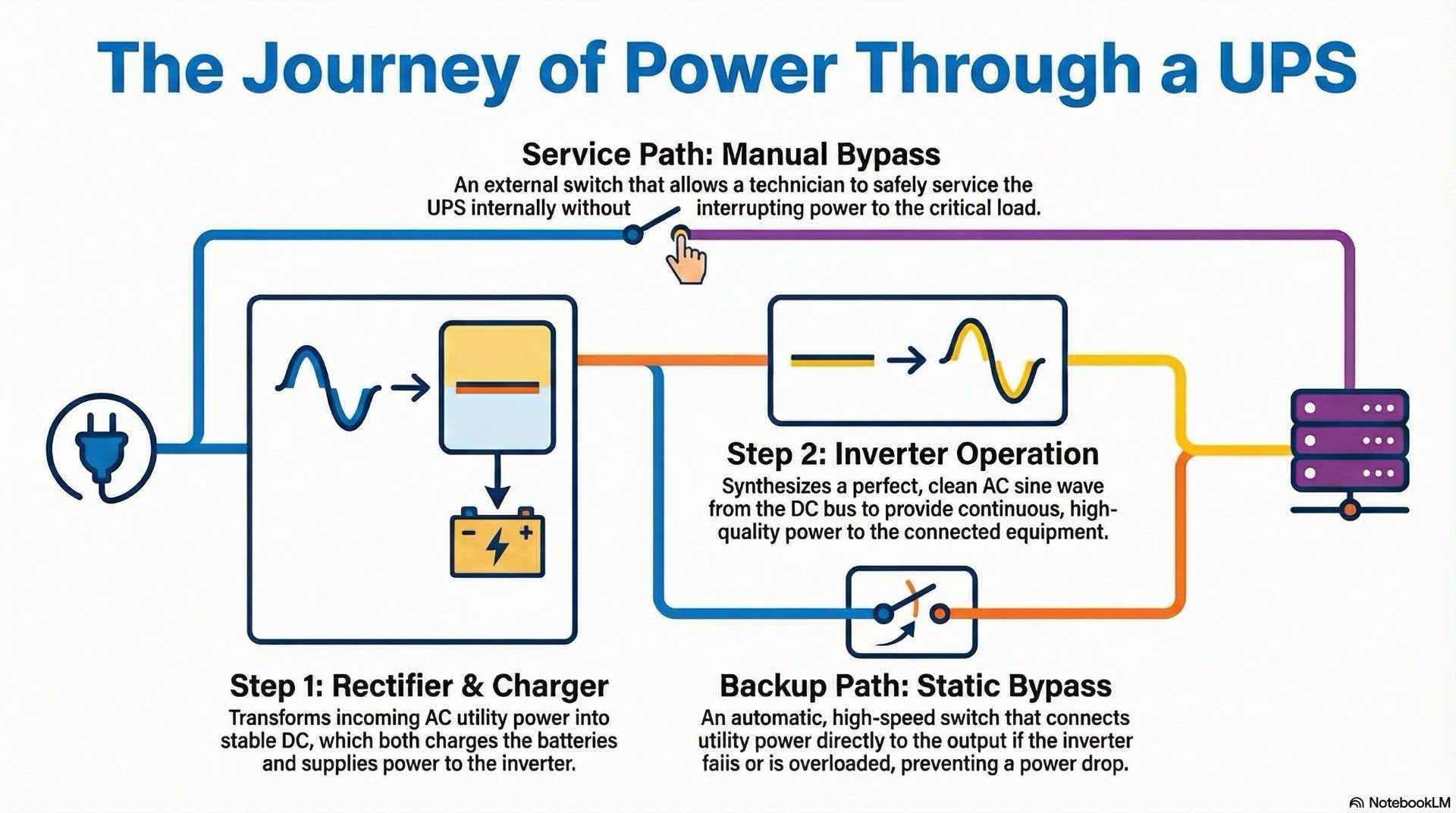

Rectifier and Charger Functions in a UPS System

Rectifiers transform three-phase AC into high-voltage DC that feeds the inverter in every UPS system. This first stage of power conditioning converts incoming utility power. Silicon-controlled rectifiers in basic UPS topologies use thyristors gated at precise phase angles. Insulated-gate bipolar transistors in modern UPS topologies switch faster with lower losses, improving power conditioning efficiency above 97 percent.

Charger circuitry optimizes battery technologies by monitoring voltage, current, and temperature. Bulk charge pushes current at constant level until voltage reaches absorption setpoint in all battery technologies. Float charge holds batteries at maintenance voltage without overcharging. Proper charging through effective power conditioning extends service life across all battery technologies. Different UPS topologies implement charging algorithms optimized for specific battery technologies, affecting overall UPS maintenance requirements.

Inverter Operation and Output Waveform Quality

Inverters synthesize sinusoidal AC by pulse-width modulation of DC bus voltage in every UPS system. This critical power conditioning stage produces clean output power. IGBTs in modern UPS topologies switch thousands of times per second, creating pulses that average to smooth sine. Advanced controllers sample output through power conditioning feedback loops 10,000 times per cycle.

Total harmonic distortion below 3 percent from proper power conditioning ensures compatibility with sensitive loads. Voltage regulation through precise power conditioning holds ±1 percent from no-load to full-load. Frequency stability through inverter-based power conditioning stays within 0.01 Hz. Effective power conditioning at the inverter stage protects connected equipment across all UPS topologies. Regular UPS maintenance verifies power conditioning performance remains within specification.

Static Bypass Switch and Transfer Logic in UPS System

Static bypass uses back-to-back thyristors to connect utility input directly to output in most UPS topologies. When inverter overloads or faults, bypass activates to prevent load dropout. Manual maintenance bypass in professional UPS topologies lets you service inverter while keeping equipment online. Different UPS topologies implement bypass circuits with varying complexity affecting power conditioning continuity.

Smart logic monitors bypass and inverter sync before transferring in advanced UPS topologies. Phase angle must match within 5 degrees for seamless power conditioning transfers. If utility drifts out of tolerance, bypass won’t close in properly designed UPS topologies—instead, inverter rides through on battery technologies until grid stabilizes. This logic appears across most modern UPS topologies, supporting uninterrupted power conditioning. Bypass testing forms an essential UPS maintenance task.

Manual Maintenance Bypass and Service Considerations

External manual bypass panels in serviceable UPS topologies give technicians physical access to isolation points. Close input and output breakers around bypass contactor, then open UPS system breakers. You can now service components without risking downtime in properly designed UPS topologies. This capability supports efficient UPS maintenance procedures and minimizes interruption to power conditioning.

Always verify bypass path before opening breakers during UPS maintenance. Check voltage phase rotation in three-phase UPS topologies. Confirm bypass breaker ratings exceed expected load by 25 percent minimum across all UPS topologies. Document bypass procedures specific to your UPS topologies in maintenance manuals. These UPS maintenance steps prevent service-related outages while ensuring continuous power conditioning.

Battery Technologies for UPS Systems

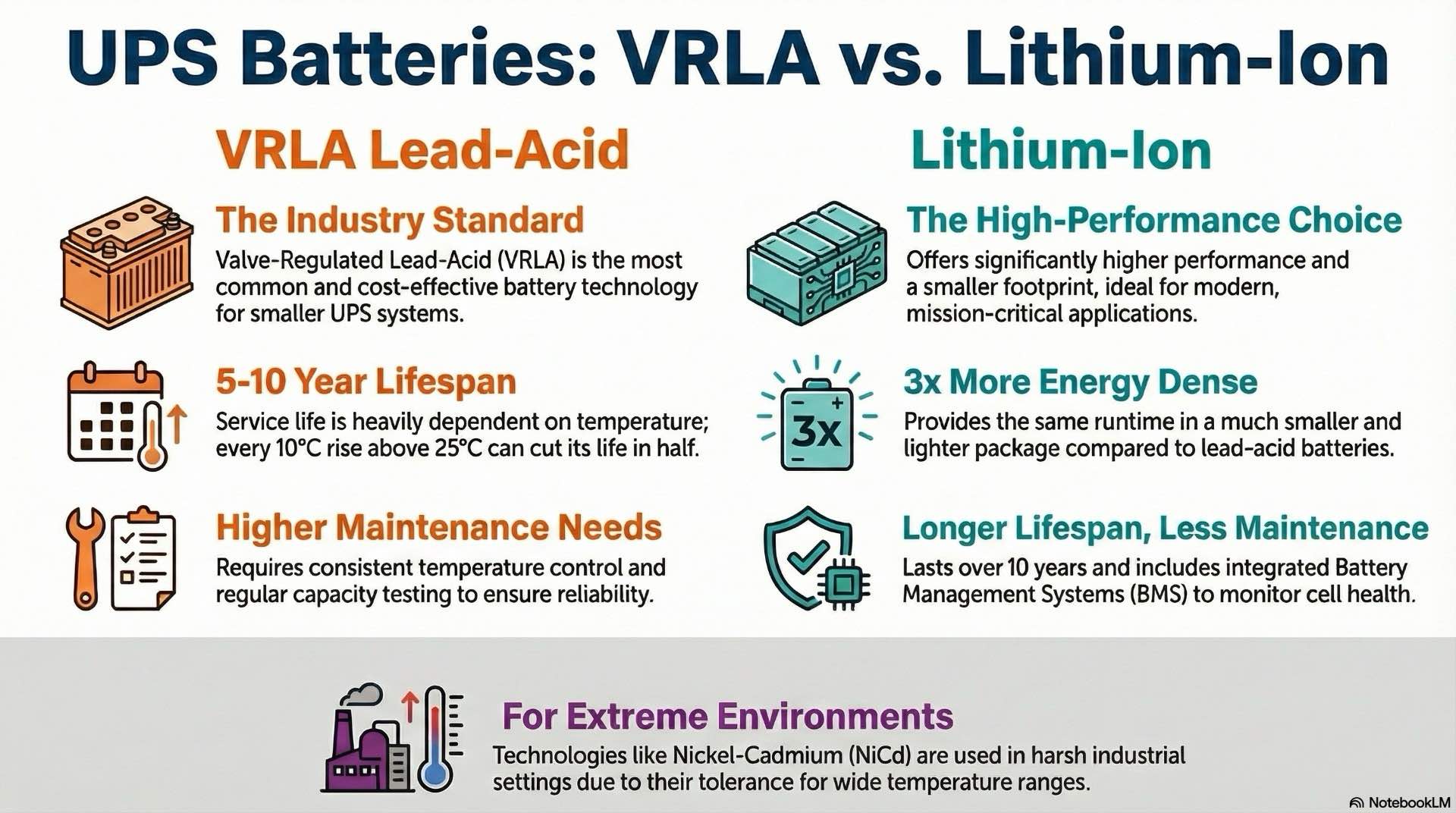

VRLA Lead-Acid Batteries for UPS System

Valve-regulated lead-acid represents the most common among battery technologies for smaller UPS system installations. VRLA battery technologies recombine hydrogen and oxygen internally, eliminating water addition. Absorbed glass mat separates plates in this type of battery technologies. Gel-cell battery technologies suspend electrolyte in silica gel for better vibration tolerance.

VRLA strings in these battery technologies deliver 12V per block. Typical capacity in VRLA battery technologies runs 100 to 200 amp-hours at C8 discharge rate. Expect 5 to 10 years of service life with proper UPS maintenance; every 10°C above 25°C cuts life in half for most battery technologies. Temperature control becomes critical with these battery technologies requiring consistent UPS maintenance attention.

Lithium-Ion Batteries in Modern UPS System

Lithium-ion chemistry offers three times the energy density of lead-acid battery technologies. You need fewer cabinets with lithium-ion battery technologies for equivalent runtime. Internal resistance stays lower across wider state-of-charge range in lithium-ion battery technologies, so voltage sag during discharge is minimal. Lithium-ion battery technologies transform UPS system footprint requirements significantly.

Battery management systems integrated with modern battery technologies monitor every cell’s voltage and temperature. Balancing circuits in advanced battery technologies ensure uniform charge distribution. Lithium-ion battery technologies handle frequent deep cycles without sulfation—ideal for sites with weekly generator tests. These battery technologies require less UPS maintenance than lead-acid battery technologies, though initial costs run higher. Power conditioning systems must accommodate the different voltage profiles of lithium-ion battery technologies.

NiCd and Other Specialized UPS Battery Options

Nickel-cadmium battery technologies operate across wider temperature extremes than lead-acid. You’ll find NiCd battery technologies in industrial applications where ambient swings from -20°C to 50°C. NiCd battery technologies tolerate deep discharge and rapid recharge without damage. These specialized battery technologies suit harsh environments but cadmium creates disposal challenges.

High-temperature VRLA battery technologies use sealed construction rated to 40°C continuous operation. Flooded lead-acid battery technologies still appear in large utility-scale installations where UPS maintenance staff can perform regular electrolyte checks. Supercapacitors provide alternative energy storage when traditional battery technologies aren’t economical for 5-second holdups. Selecting appropriate battery technologies depends on application requirements, environmental conditions, and available UPS maintenance resources.

Battery Runtime, Aging, and Replacement Planning

Calculate runtime by dividing capacity of your selected battery technologies by load current. Apply correction factors for discharge rate, temperature, and age across all battery technologies. A 200Ah string at 25°C delivering 40A gives 5 hours on paper; real-world performance drops after 3 years of service with any battery technologies. Aging affects all battery technologies similarly, making regular UPS maintenance essential.

Capacity testing every 12 months tracks degradation trends in your battery technologies. Impedance testing identifies weak cells before they fail regardless of battery technologies used. Replace strings when capacity falls below 80 percent of nameplate rating across all battery technologies. Don’t mix old and new batteries—mismatched impedance causes imbalanced current in all battery technologies. Proper UPS maintenance includes systematic battery testing across all battery technologies, ensuring reliable power conditioning support.

Power Distribution and Conditioning with UPS Systems

Input Power Quality, THD, and Power Factor

Input current drawn by rectifiers contains harmonics requiring power conditioning. Six-pulse rectifiers inject 5th, 7th, 11th, and 13th harmonics; twelve-pulse designs in better UPS topologies reduce but don’t eliminate them through improved power conditioning. Passive harmonic filters provide basic power conditioning by shunting specific frequencies to ground. Input power conditioning protects upstream distribution equipment.

Active front-end rectifiers in premium UPS topologies provide superior power conditioning by drawing sinusoidal current at unity power factor. Input total harmonic distortion drops below 5 percent through active power conditioning, meeting IEEE 519 requirements without external filters. Unity power factor from advanced power conditioning means apparent power equals real power. These power conditioning techniques appear in high-efficiency UPS topologies requiring minimal UPS maintenance.

Output Voltage Regulation and Frequency Stability

Load changes cause instantaneous voltage sags until power conditioning control loops compensate. Digital signal processors in modern power conditioning systems sample output 10,000 times per cycle. Static regulation through precise power conditioning holds ±1 percent from no-load to full-rated current. Tight regulation is a hallmark of effective power conditioning across all quality UPS topologies.

Frequency control through inverter-based power conditioning locks output to precise 50.000 or 60.000 Hz. Internal oscillator in power conditioning systems uses crystal reference accurate to ±0.01 percent. When synchronized to utility, inverter power conditioning tracks input frequency to enable seamless transfers. In battery mode, power conditioning maintains set frequency regardless of load power factor. This power conditioning capability prevents timing drift in connected equipment while supporting uninterrupted operation during UPS maintenance activities.

Surge Protection, Filtering, and Noise Suppression

Metal-oxide varistors in power conditioning circuits clamp transients above 800V peak. Gas discharge tubes provide additional power conditioning by shunting lightning-induced surges to ground. Common-mode chokes in power conditioning filters attenuate radio-frequency interference generated by inverter switching. Multiple layers of power conditioning protect sensitive loads across all UPS topologies.

Output isolation transformers in power conditioning systems break ground loops between utility and load. Electrostatic shields provide enhanced power conditioning by blocking capacitive coupling of transients. Low-pass filters in power conditioning circuits remove switching noise above 20kHz. Comprehensive power conditioning eliminates virtually all disturbances, protecting equipment connected to equipment. Regular UPS maintenance verifies all power conditioning components function correctly.

Integrating UPS System with PDUs and Distribution Panels

Uninterruptible supplies feed rack power distribution units through hardwired connections extending power conditioning to final loads. PDUs provide circuit breakers and receptacles for individual servers, maintaining power conditioning quality. Intelligent units measure current per outlet, supporting balanced loading across UPS topologies. Proper integration maximizes UPS system effectiveness and power conditioning benefits.

Automatic transfer switches swap between UPS system output and bypass utility during UPS maintenance or faults. Static transfer switches use solid-state devices for millisecond-speed transfers maintaining power conditioning continuity. Mechanical contactors offer higher surge capacity but introduce 50 to 100 millisecond delays affecting power conditioning. Selection depends on load sensitivity and available UPS topologies supporting your power conditioning requirements.

UPS System Sizing and Load Calculations

Determining Critical Load Power and Capacity Margins

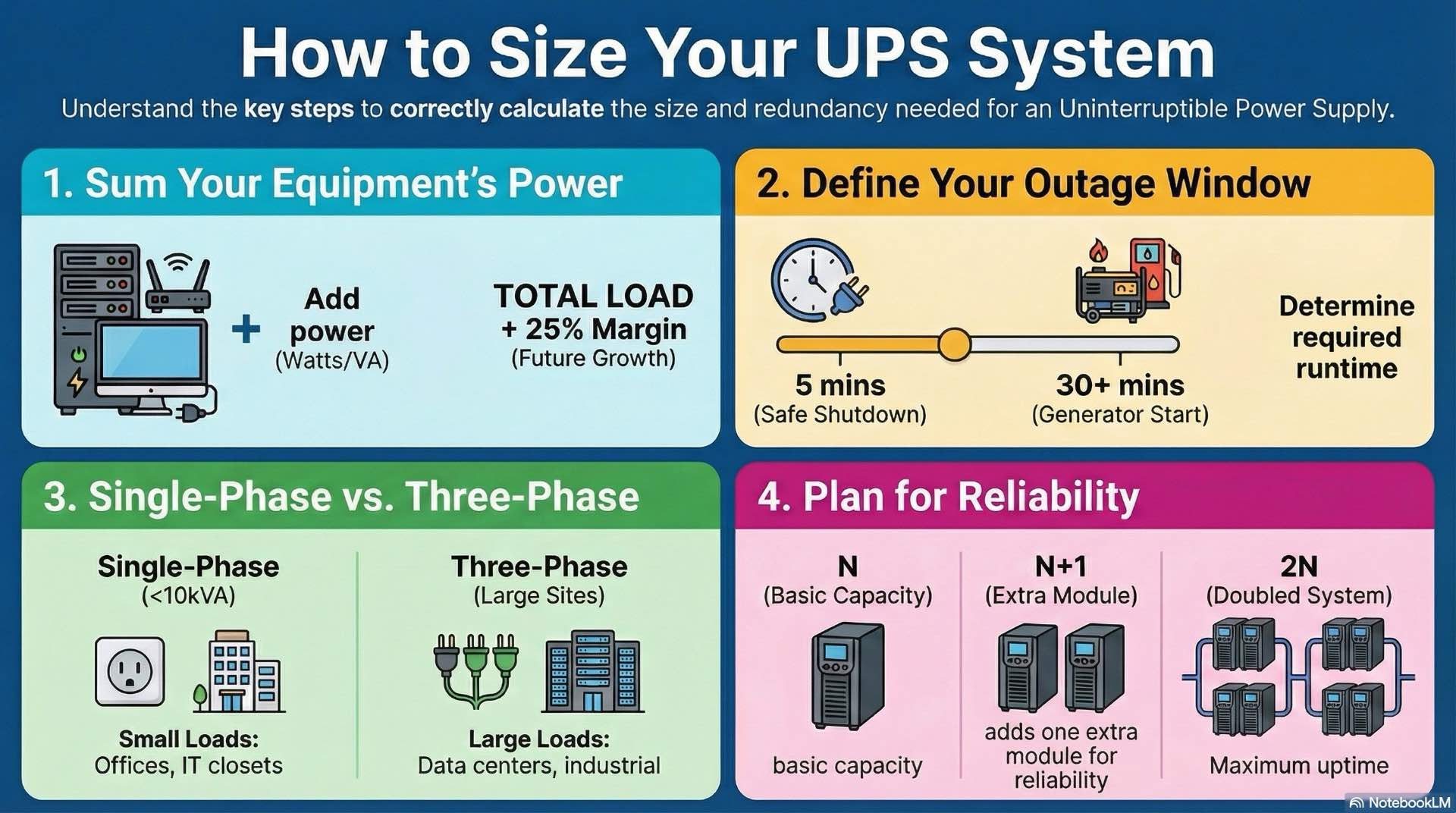

Survey every piece of equipment connected to equipment. Record nameplate power in watts or VA for each load served by your UPS system. Sum all loads protected by the installation; that’s your minimum rating. Add 25 percent margin to equipment sizing for future expansion. Different UPS topologies handle power factor differently, affecting total UPS system capacity.

Distinguish between real power in watts and apparent power in volt-amperes when sizing your UPS system. Switching power supplies draw current with poor power factor in any UPS system. Size your UPS system based on whichever is higher: total watts divided by 0.9 power factor, or total VA. Different UPS topologies provide varying power factor capabilities requiring different power conditioning approaches.

Calculating UPS System Runtime Requirements

Define how long loads must stay online during outage through these units. Typical targets range from 5 minutes for orderly shutdown to 30 minutes until generator starts. Multiply load power protected by your UPS system by required time to get energy storage needed. Battery technologies available for the equipment determine achievable runtime for given cabinet space. Power conditioning efficiency affects actual runtime delivered by battery technologies.

Battery manufacturers publish capacity tables for different battery technologies at various discharge rates. Faster discharge delivers less total energy due to internal losses in all battery technologies. A 100Ah battery at 10-hour rate provides 1000 watt-hours; at 1-hour rate typical in UPS system applications, you get 800 watt-hours with most battery technologies. This behavior applies across all battery technologies used in UPS system designs.

Single-Phase vs Three-Phase UPS System Sizing

Single-phase UPS system units dominate below 10kVA. You’ll find these UPS system designs in small server rooms and network closets. Output voltage from single-phase UPS system units is 120V or 230V line-to-neutral. Single-phase UPS topologies suit distributed installations with modest power conditioning needs.

Three-phase UPS system designs scale from 10kVA to megawatts. Industrial sites and data centers use three-phase UPS system distribution at 208V, 400V, or 480V. Each phase in three-phase UPS system designs carries one-third of total load. Modular three-phase UPS topologies let you start with 30kVA and add modules quarterly. Three-phase UPS topologies provide higher power density and more sophisticated power conditioning than single-phase UPS system units.

Redundancy Concepts: N, N+1, and 2N UPS System Designs

N configuration UPS system provides exactly enough capacity to carry load. One failure in N configuration UPS system causes immediate shutdown. It’s the simplest UPS system option when downtime risk is acceptable. Basic UPS topologies work well in N configuration UPS system designs for non-critical loads with minimal power conditioning requirements.

N+1 redundant UPS system adds one extra module beyond minimum required capacity. Load runs on N modules in N+1 UPS system; the +1 sits ready as standby. Any single failure in N+1 UPS system lets remaining modules handle load. Parallel redundant UPS topologies use multiple units tied through static transfer switches. This N+1 UPS system arrangement provides continuous power conditioning even during module failure. UPS maintenance can proceed on individual modules in N+1 UPS system without affecting load.

2N redundant UPS system doubles everything: two independent paths from utility to load. Dual-corded servers connect to both paths in 2N UPS system. Simultaneous failures in one path don’t affect availability in 2N UPS system. This costs twice as much but delivers highest reliability for mission-critical operations requiring uninterrupted power conditioning. Advanced UPS topologies enable 2N UPS system architectures with full redundancy in power conditioning, battery technologies, and all components.

UPS Installation and Commissioning Best Practices

Site Preparation, Cabling, and Power Layout

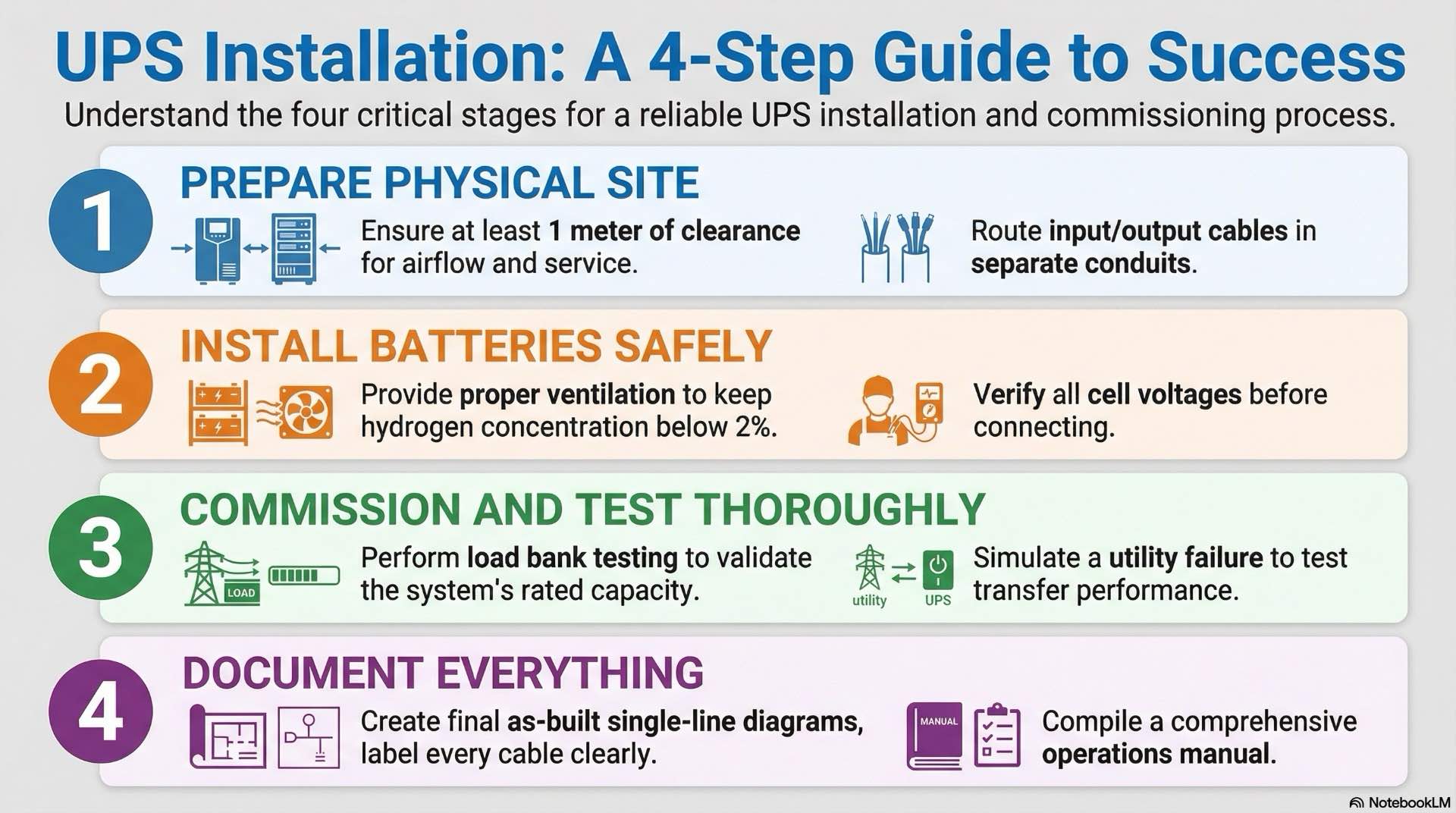

Electrical room must provide adequate space around equipment for airflow and service access. Maintain 1 meter clearance on all sides of UPS system per manufacturer requirements. Install concrete housekeeping pads if UPS system floor loading exceeds 1000 kg per square meter. Proper layout facilitates future UPS maintenance activities on the system.

Route input and output cables for the equipment in separate conduits to prevent fault coupling. Use copper conductors sized per NEC ampacity tables for the equipment installation. Torque all terminal connections in the unit to specified values using calibrated wrenches. Cable management affects long-term reliability of the installation and simplifies power conditioning verification during UPS maintenance.

Battery Installation, Safety, and Ventilation

Battery strings in any UPS system produce hydrogen during charging regardless of battery technologies used. Provide ventilation to keep hydrogen concentration below 2 percent around equipment batteries. Mount battery technologies on seismic-rated racks if your UPS system site is in earthquake zone. Connect intercell and interblock cables for the equipment battery technologies with properly sized lugs.

Check every cell voltage before closing battery breaker in the unit. Voltage across string should equal number of cells times 2.27V for lead-acid battery technologies. Mark your UPS system cabinet with arc flash hazard labels. Install battery disconnect switches within sight of battery cabinets for the equipment. Safety precautions apply to all battery technologies used in any UPS system supporting critical power conditioning.

Commissioning Tests and Acceptance Procedures

Perform insulation resistance tests on AC input, output, and DC circuits of the installation. Measure at 1000V DC for one minute on the system; resistance should exceed 1 megohm. Verify phase rotation of the installation matches building distribution. Confirm grounding continuity from the unit cabinet frame to building electrode system. Commissioning validates power conditioning performance of the installation.

Execute factory acceptance tests per written procedures for the equipment. Load bank testing validates rated capacity and runtime of the installation with installed battery technologies. Simulate utility loss to confirm your UPS system transfer to battery happens within specification. Test static bypass of the installation by intentionally overloading inverter. These tests verify proper operation of all UPS topologies and power conditioning systems. Document results for future UPS maintenance reference.

Documentation, Labelling, and As-Built Records

Single-line diagrams show every breaker, switch, and connection point in the unit. Update drawings to reflect field changes during your UPS system installation. Label every cable in the unit with origin, destination, voltage level, and circuit number. Complete documentation streamlines future UPS maintenance activities and simplifies ongoing UPS maintenance on the system.

Create operations manual covering startup, shutdown, and emergency procedures for the equipment. Include contact information for UPS maintenance contractors. Photograph UPS system cabinet interiors before closing doors. Documentation supports long-term management of the installation, battery technologies, and power conditioning equipment.

UPS Operations, Monitoring, and Maintenance

Local and Remote UPS Monitoring Interfaces

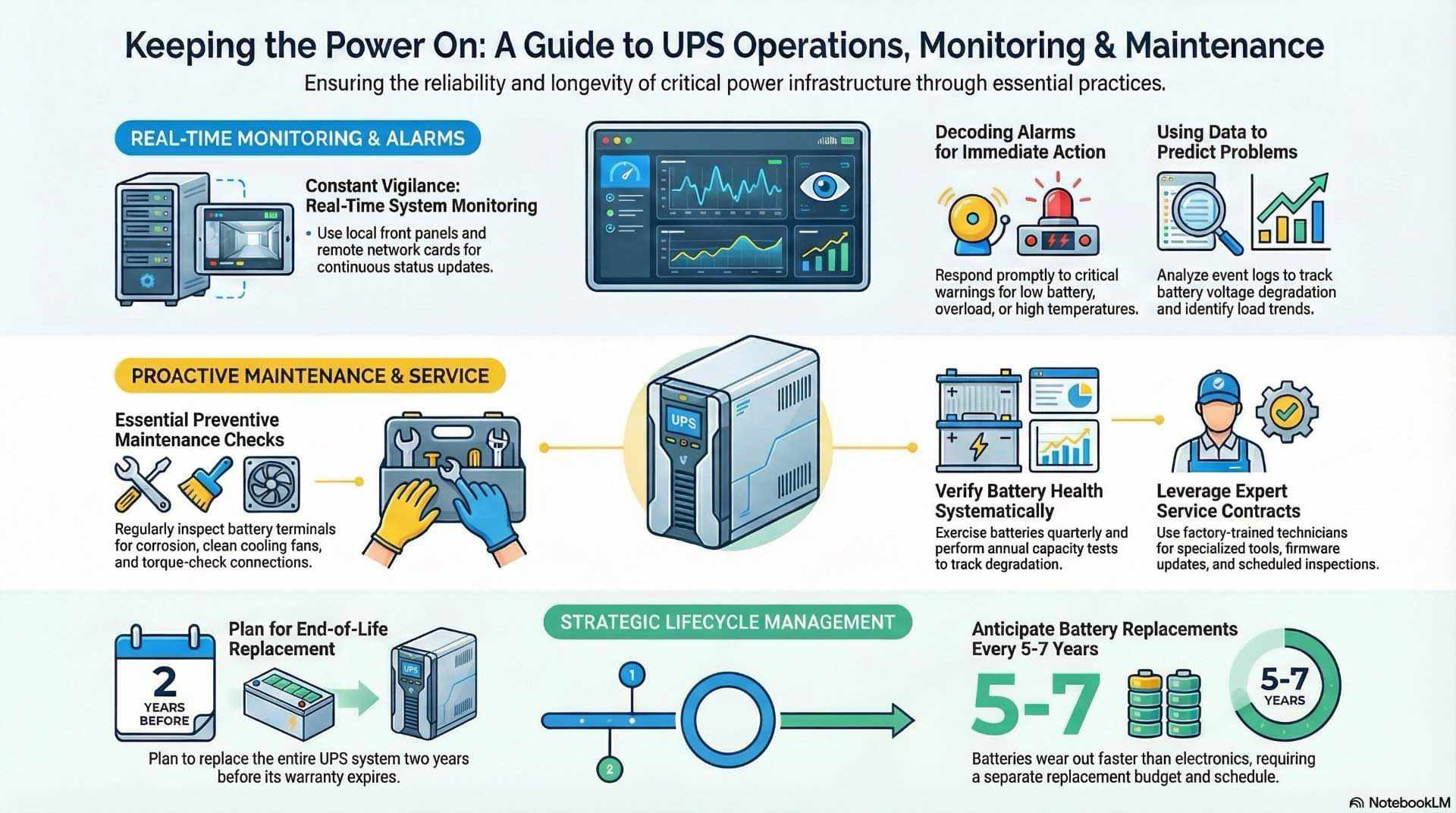

Front panel displays on the system show input voltage, output voltage, battery voltage, load percentage, and estimated runtime. Navigate menus to access alarm history and event logs on the system. Network interface cards enable SNMP polling so building management systems track your UPS system remotely. Monitoring capabilities vary among different UPS topologies but support essential UPS maintenance functions.

Cloud monitoring platforms aggregate data from multiple UPS system installations. You’ll see real-time dashboards comparing load trends across your UPS system fleet. Email and SMS alerts notify staff when your UPS system alarms occur. Mobile apps let technicians check UPS system health from anywhere. Remote monitoring reduces UPS maintenance response time for the equipment while tracking power conditioning performance.

Alarm Handling, Event Logs, and Trend Analysis

Low battery voltage on the system warns that runtime will soon expire. Overload alarms indicate equipment connected to equipment exceeds rated capacity. Overtemperature conditions on the system point to cooling problems. Prompt alarm response is essential for effective UPS maintenance on the system.

Event logs on the system timestamp every alarm, transfer, and configuration change. Export logs monthly for trend analysis of the installation. Graph battery voltage over time to spot gradual degradation in your battery technologies. Compare load current curves to identify equipment failures affecting your UPS system. Log analysis supports predictive UPS maintenance strategies for the equipment and power conditioning equipment.

Preventive Maintenance and Health Checks

Inspect battery terminals on the system for corrosion quarterly. Measure voltage across each block in your battery technologies. Torque-check power connections on the system annually. These essential UPS maintenance tasks prevent unexpected failures through systematic UPS maintenance procedures in the unit.

Clean dust from cooling fans on the system monthly. Dirty filters reduce airflow and raise internal temperatures affecting your UPS system. Test transfer to bypass under controlled conditions to confirm your UPS system switching logic works. Exercise batteries quarterly to verify capacity of your battery technologies hasn’t dropped below 80 percent. Regular UPS maintenance extends equipment life of the installation while maintaining power conditioning quality.

Service Contracts and Lifecycle Management

Annual service contracts provide scheduled inspections by factory-trained technicians for the equipment. They bring specialized tools, firmware updates, and spare parts unavailable to in-house UPS maintenance staff. Contracts typically cover labor for the equipment but charge separately for replacement components. Professional UPS maintenance and scheduled UPS maintenance ensure optimal performance of the installation, battery technologies, and power conditioning equipment.

Plan end-of-life replacement of the installation 2 years before warranty expires. Lead times for new systems stretch 16 to 26 weeks for most UPS topologies. Overlap old and new during cutover to avoid downtime from the unit. Budget for battery replacements every 5 to 7 years; battery technologies wear out faster than electronics in the unit. Lifecycle planning considers both your UPS system components and battery technologies replacement cycles, factoring in changing power conditioning requirements.

UPS Safety, Policy, and Compliance

Electrical Safety and Lockout Tagout Procedures

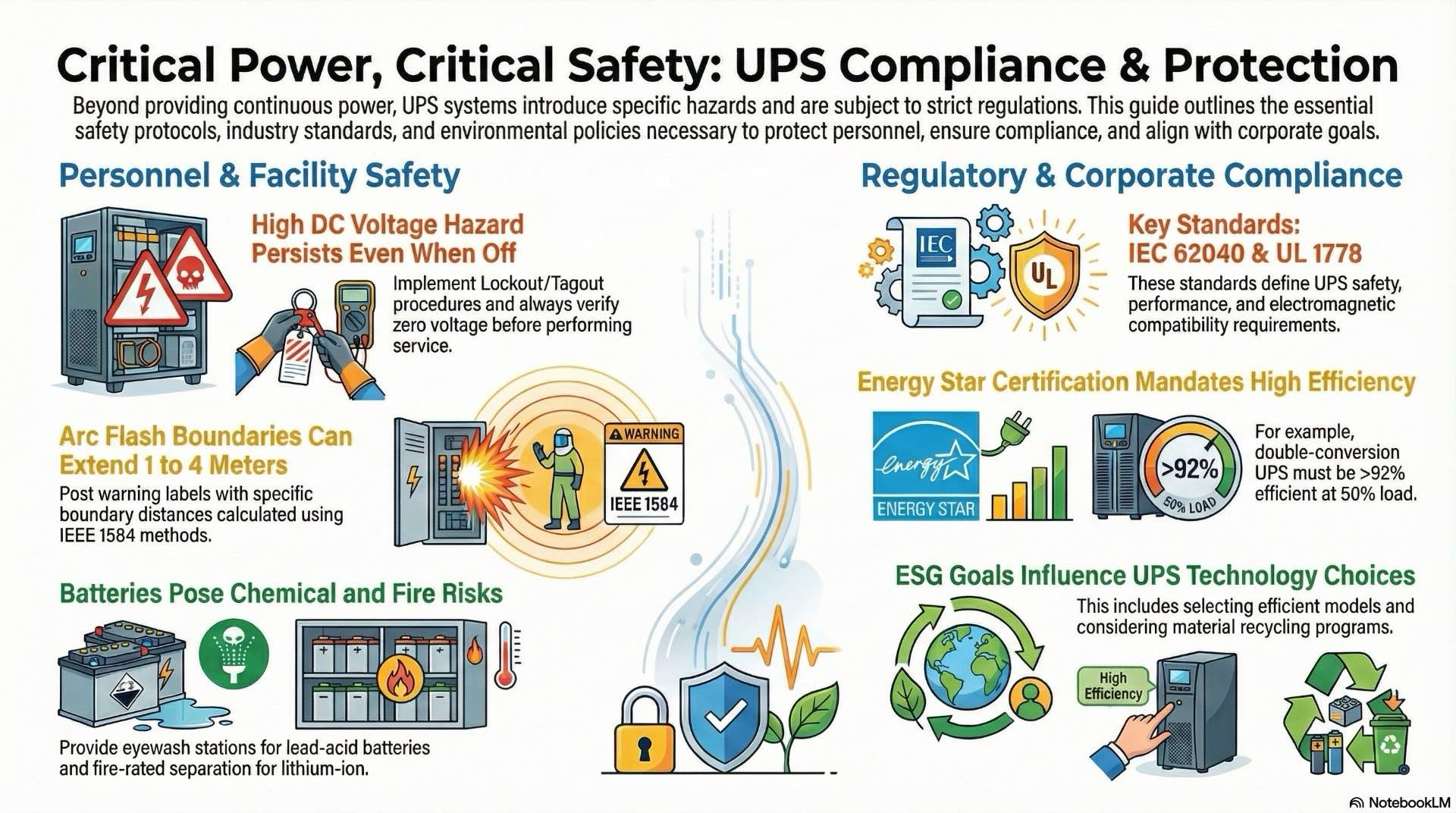

High DC voltages inside battery cabinets of the installation remain energized even when input breaker opens. Always verify zero voltage before touching conductors in the unit. Implement lockout tagout program that requires personal locks on every energy isolation point during UPS maintenance on the system. Safety protocols apply to all UPS topologies and battery technologies used in any UPS system.

Arc flash boundaries extend 1 to 4 meters around equipment depending on available fault current. Calculate incident energy for the equipment using IEEE 1584 methods. Post labels showing boundary distances for the equipment. Proper safety procedures protect UPS maintenance personnel working on the system, battery technologies, and power conditioning equipment.

Battery Safety, Spill Control, and Fire Protection

Lead-acid electrolyte in battery technologies for the equipment contains sulfuric acid at 1.215 specific gravity. Provide eyewash station within 10 meters of the installation battery room. Train staff on spill response for your battery technologies. Safety requirements vary by battery technologies used in the unit.

Lithium-ion thermal runaway in certain battery technologies produces intense heat. Install smoke detection tied to building fire alarm around equipment. Provide 30 minutes of fire-rated separation between your UPS system battery rooms and occupied spaces. Fire protection must match specific battery technologies deployed in the unit supporting critical power conditioning.

Standards and Certifications for UPS System

IEC 62040 defines performance requirements and test methods for the equipment. Part 1 covers safety of the installation, part 2 addresses electromagnetic compatibility, part 3 specifies performance classifications. UL 1778 approval confirms North American safety compliance of the installation. Standards apply to all UPS topologies uniformly ensuring consistent power conditioning.

Energy Star certification requires minimum efficiency thresholds for the equipment: 92 percent at 50 percent load for double-conversion UPS topologies. ITIC curve shows voltage-time tolerance for IT equipment; your UPS system must keep output within ITIC boundaries. Compliance ensures effective power conditioning performance from the unit across all UPS topologies.

Environmental, ESG, and Corporate Policy Alignment

Corporate sustainability goals drive procurement toward high-efficiency designs for the equipment. Lithium-ion battery technologies contain cobalt mined under questionable labor practices. Lead-acid recycling programs recover 99 percent of materials from older battery technologies. ESG considerations affect battery technologies selection for the equipment.

Publish energy consumption metrics from the unit as part of ESG reporting. Track PUE improvements attributed to efficient power conditioning in the unit. Participate in demand response programs that shed non-critical loads while your UPS system keeps critical equipment operational. Environmental responsibility extends to UPS maintenance practices for the equipment and proper disposal of battery technologies.

UPS Application Segments and Design Scenarios

UPS System for Data Centers and IT Rooms

Hyperscale facilities deploy modular UPS topologies in hot-aisle containment pods. Each pod holds 10 to 40kW of IT load protected by dedicated UPS system units. Scalability matters because compute grows 20 percent annually—start with 50 percent capacity in the unit and add modules quarterly. Data center UPS topologies prioritize efficiency in power conditioning and modularity.

N+1 redundancy prevents single-module failures from dropping load served by your UPS system. Parallel UPS topologies share current through load-sharing busses. Network monitoring integrates with DCIM platforms for holistic tracking of the installation. Advanced battery technologies reduce footprint in space-constrained facilities while maintaining runtime for the equipment. Power conditioning must meet stringent specifications for sensitive IT equipment.

UPS System for Healthcare and Medical Equipment

Hospitals classify circuits by criticality: life-safety branch requires the most reliable UPS system. Equipment branch powers imaging systems through specialized UPS topologies. Uninterruptible supplies on life-safety circuits must meet stringent transfer time requirements. Medical UPS topologies emphasize reliability in power conditioning above all else.

Isolated power systems use transformers to decouple ground and prevent leakage currents that could shock patients. Ground fault detection monitors your UPS system for insulation failures. Lithium-ion battery technologies offer longer runtime in smaller footprints for the equipment. Power conditioning must meet medical-grade specifications across all medical UPS topologies. Regular UPS maintenance ensures life-safety systems remain operational.

UPS System for Industrial and Manufacturing Plants

Programmable logic controllers need clean power conditioning through reliable UPS topologies. Voltage sags from motor starts cause nuisance resets that halt production lines. Line-interactive UPS topologies correct sags without depleting battery technologies. Industrial environments demand robust power conditioning through hardened UPS topologies.

Three-phase UPS topologies balance load across plant distribution. Industrial-grade units tolerate 40°C ambient and high dust levels. Some installations use flywheel energy storage instead of traditional battery technologies. Battery technologies must withstand harsh conditions while supporting critical power conditioning. UPS maintenance schedules account for challenging environmental conditions.

UPS System for Commercial, Retail, and Office Buildings

Tenant spaces require right-sized UPS topologies that don’t consume excessive electrical closet space. Wall-mounted designs save floor area for the equipment. Rack-mount UPS topologies fit in IT cabinets alongside switches and servers. Commercial UPS topologies balance cost, size, and power conditioning performance.

Building management systems monitor status of the installation over BACnet or Modbus networks. Automated demand response sheds HVAC load while your UPS system keeps security, fire alarm, and emergency lighting operational. Lithium-ion battery technologies provide 10-year service life that aligns with typical lease terms, reducing replacement costs for the equipment. Integrated power conditioning ensures tenant equipment operates reliably while simplified UPS maintenance keeps operating costs manageable.

Understanding how an UPS system operates starts with selecting appropriate UPS topologies matched to load requirements. Modern battery technologies deliver longer runtime in smaller spaces, while integrated power conditioning ensures voltage stays clean under all grid conditions. Systematic UPS maintenance catches degradation before failures occur, protecting mission-critical operations across every application segment.